We provide a comprehensive selection of life science feeding bottle treatment solutions which range from decapper and recapper to small semi-automatic and fully automated systems for the simultaneous disinfection of feeding bottles and caps.

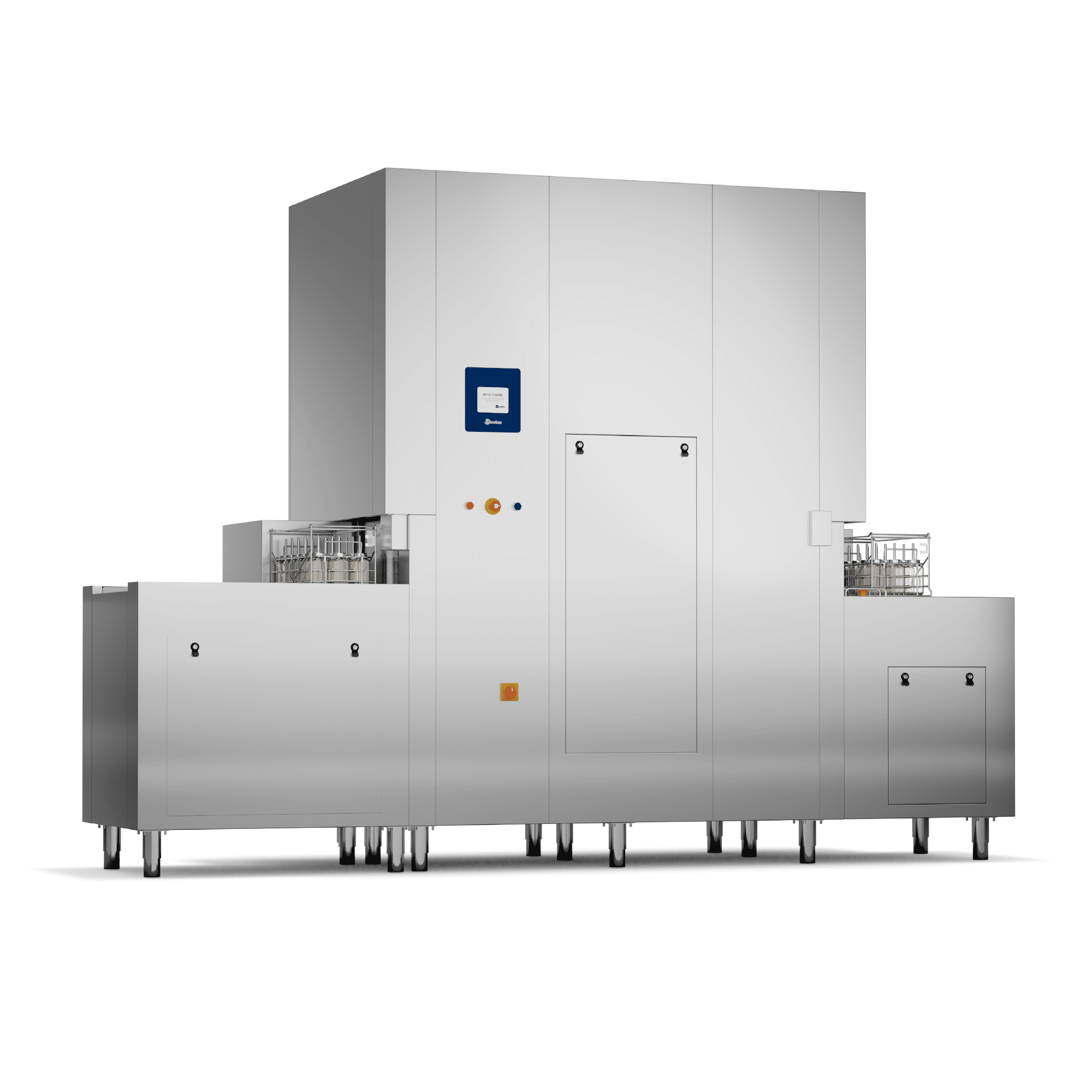

The MITO FB COMBI system is our most compact, multifunctional and automated system which provides simultaneous disinfection of feeding bottles and caps. This high-performance system offers an all-in-one solution for decapping, emptying, washing, sanitisation, filling and recapping in less than a 4 m2 footprint. It can process up to 720 bottles and 720 caps per hour and provides compatibility with robotic loading and unloading functions.

In addition to the MITO FB COMBI, we offer a range of semiautomatic feeding bottle washers with independent washing and rinsing systems, automatic detergent dosing and full bottle coverage with individual nozzles.

High productivity system processing up to 720 bottles and 720 caps per hour.

Impressive compact solution with a less than 4 m2 footprint.

Suitable for in-line and conventional barrier pass-through applications.

Decapping, emptying, washing, sanitisation, filling and recapping.

Constant monitoring and display of the current cycle status and alarms.

Integration with robotised features, or automated loading/unloading.

Discover our range of Life Science feeding bottle treatments from Steelco for life sciences.

The most compact, multifunctional and automated system for the simultaneous disinfection of feeding bottles and caps.

Semi-automatic feeding bottle washer with Independent washing and rinsing system that can process 2x18 bottle crates per cycle.

Semi-automatic feeding bottle washer disinfector with an integrated filling system which can process 1x18 bottle crate per cycle.

Here at Sychem, we understand the importance of keeping your life science lab equipment running at its highest possible potential with minimal downtime. This is why we have a team of office-based resource coordinators on hand to support you.

With a range of customisable service packages available, we can provide you with service, planned preventative maintenance (PPM), equipment validation and testing, refurbishment, and emergency breakdown support.

Our team of more than 35 highly skilled service and test personnel located throughout the UK are dedicated to maintaining and optimising your equipment.

Get in contact with our team of experts today to discuss how we can design a customisable service package for your life science facility.