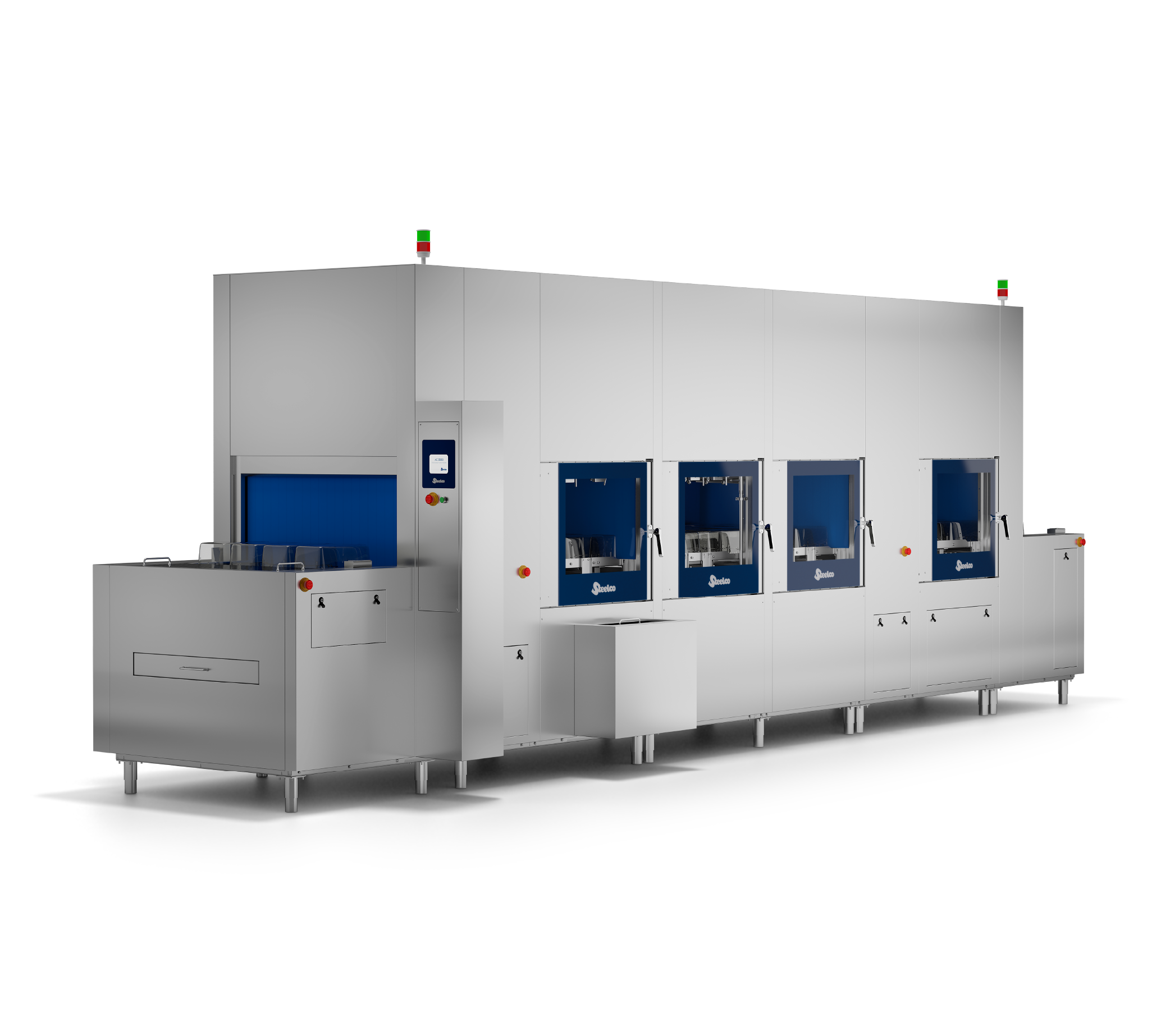

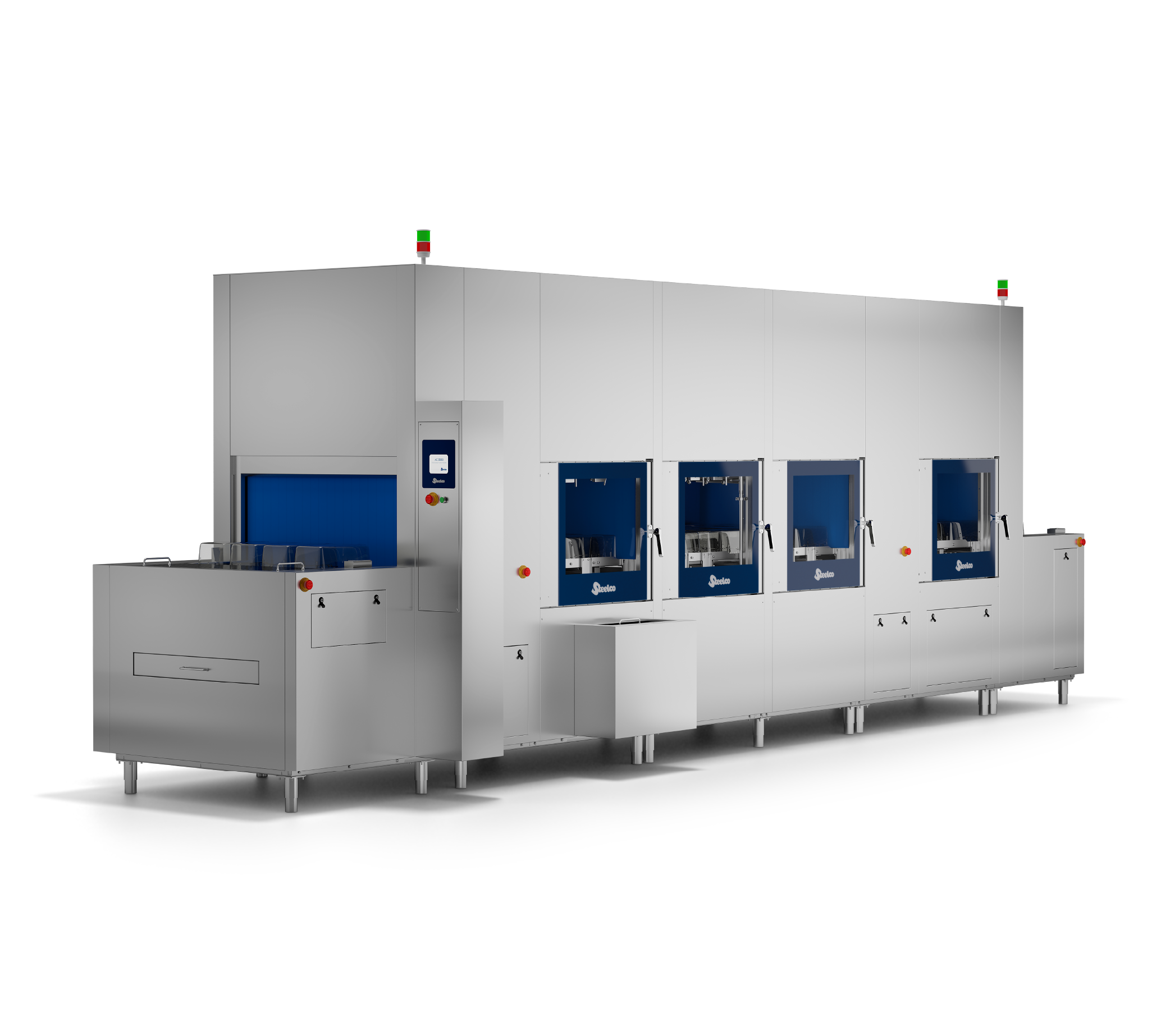

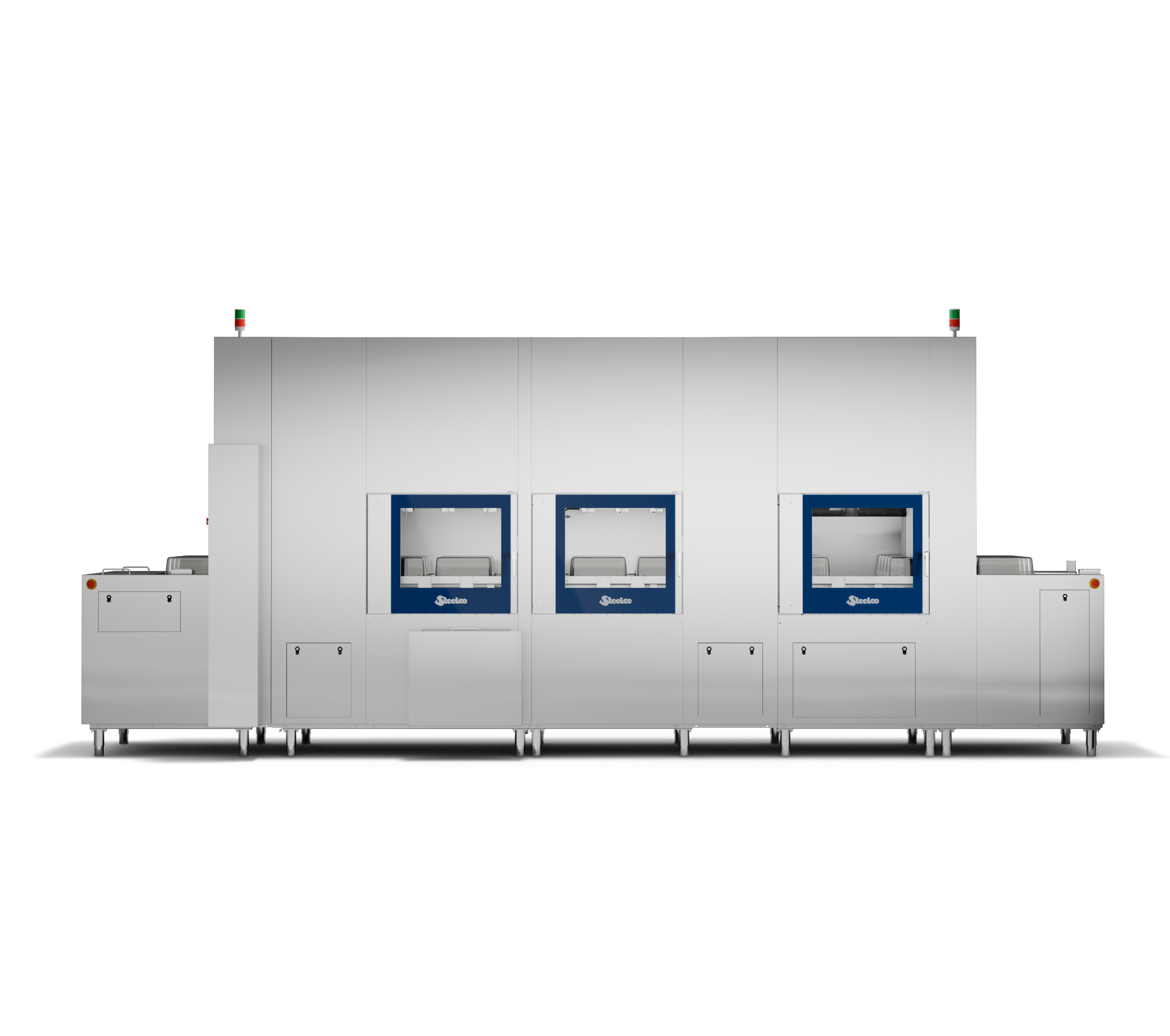

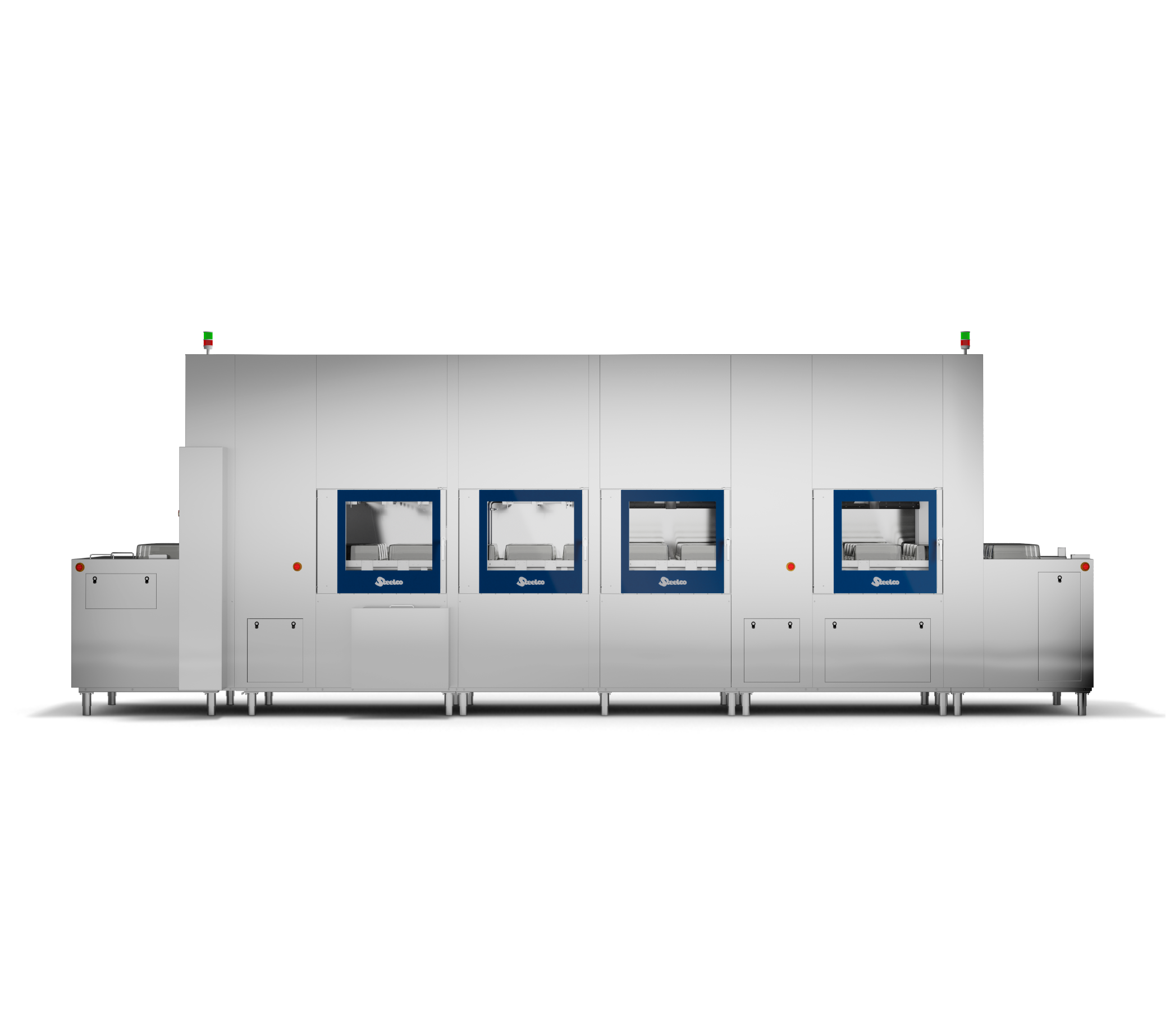

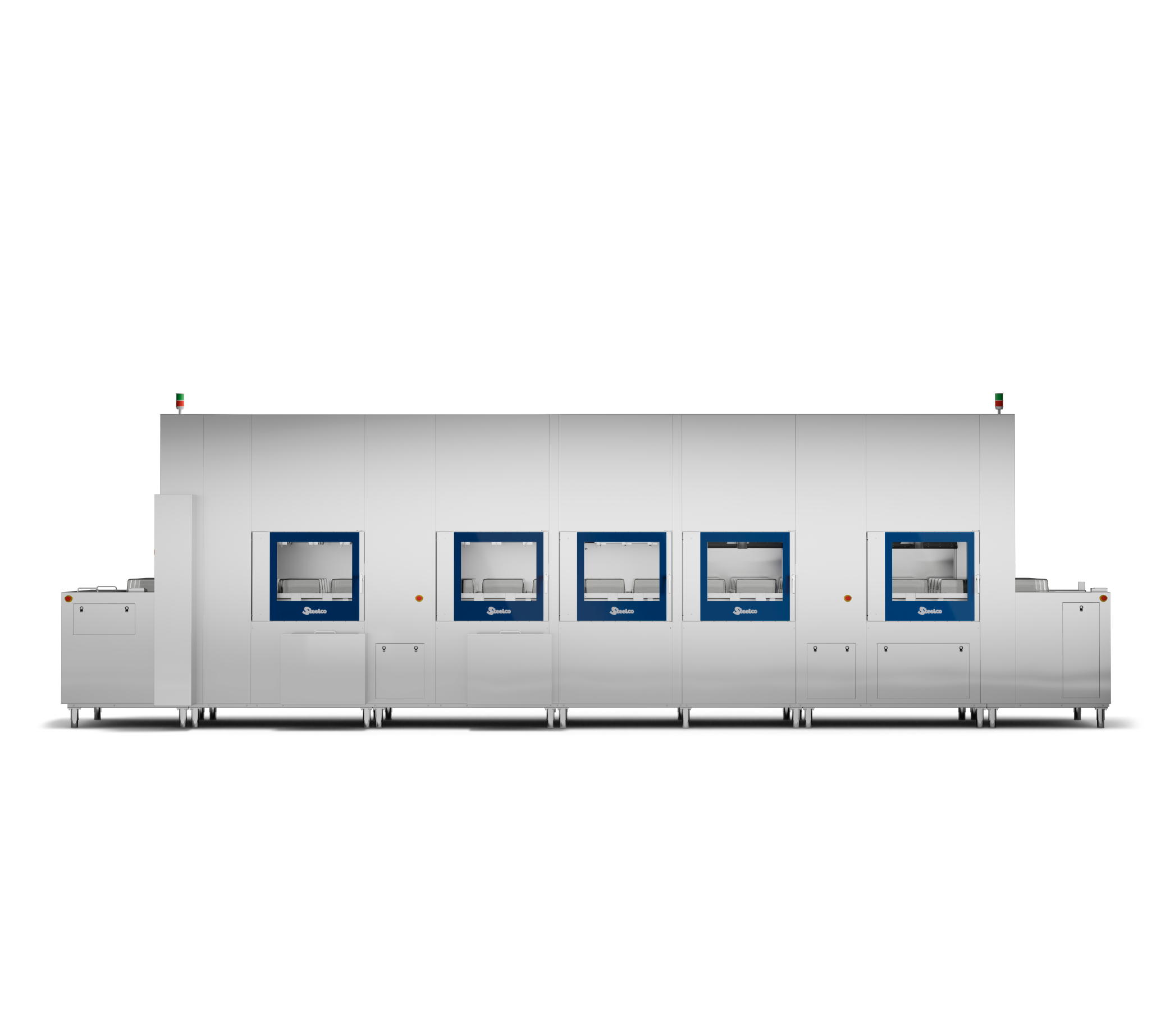

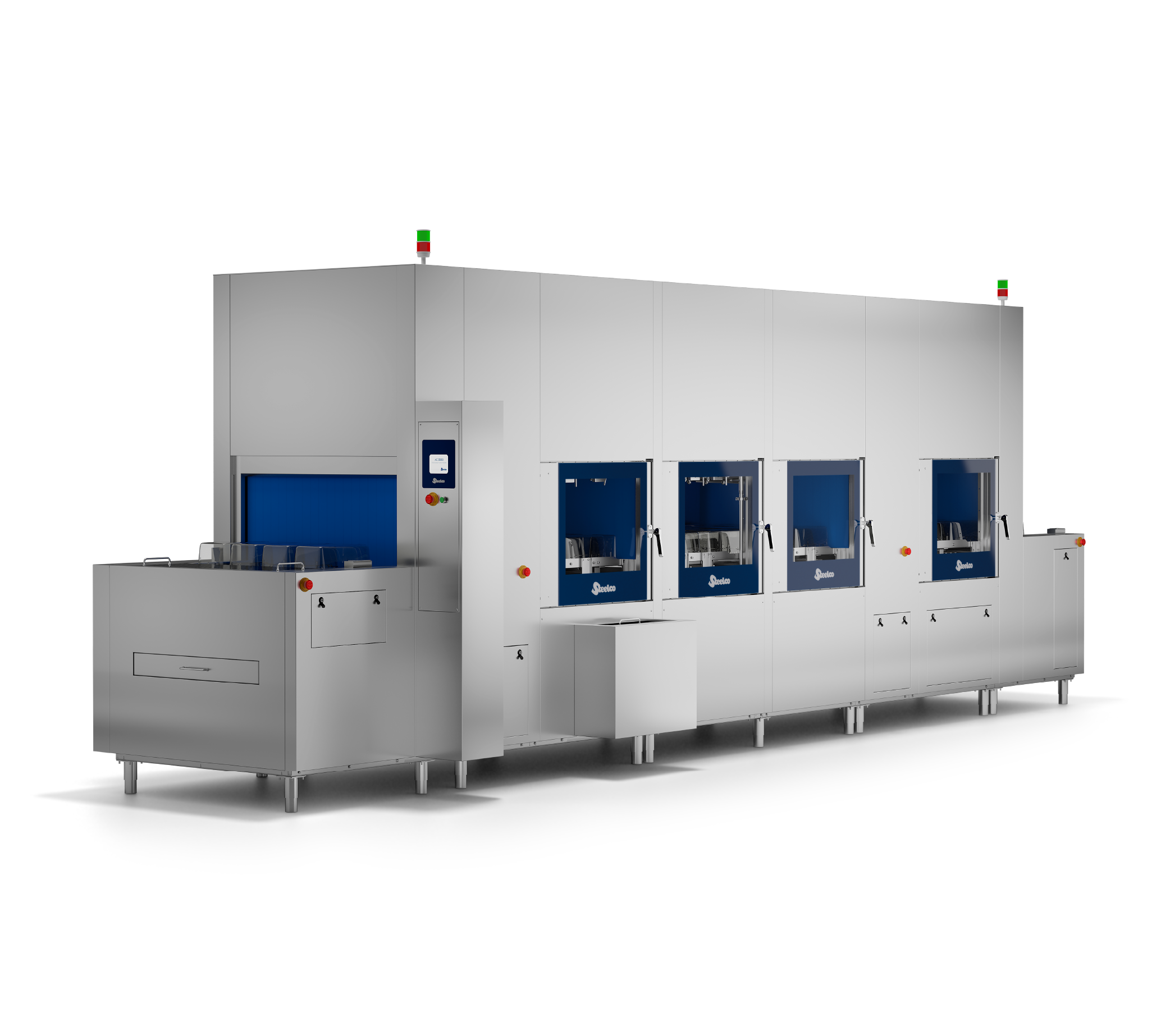

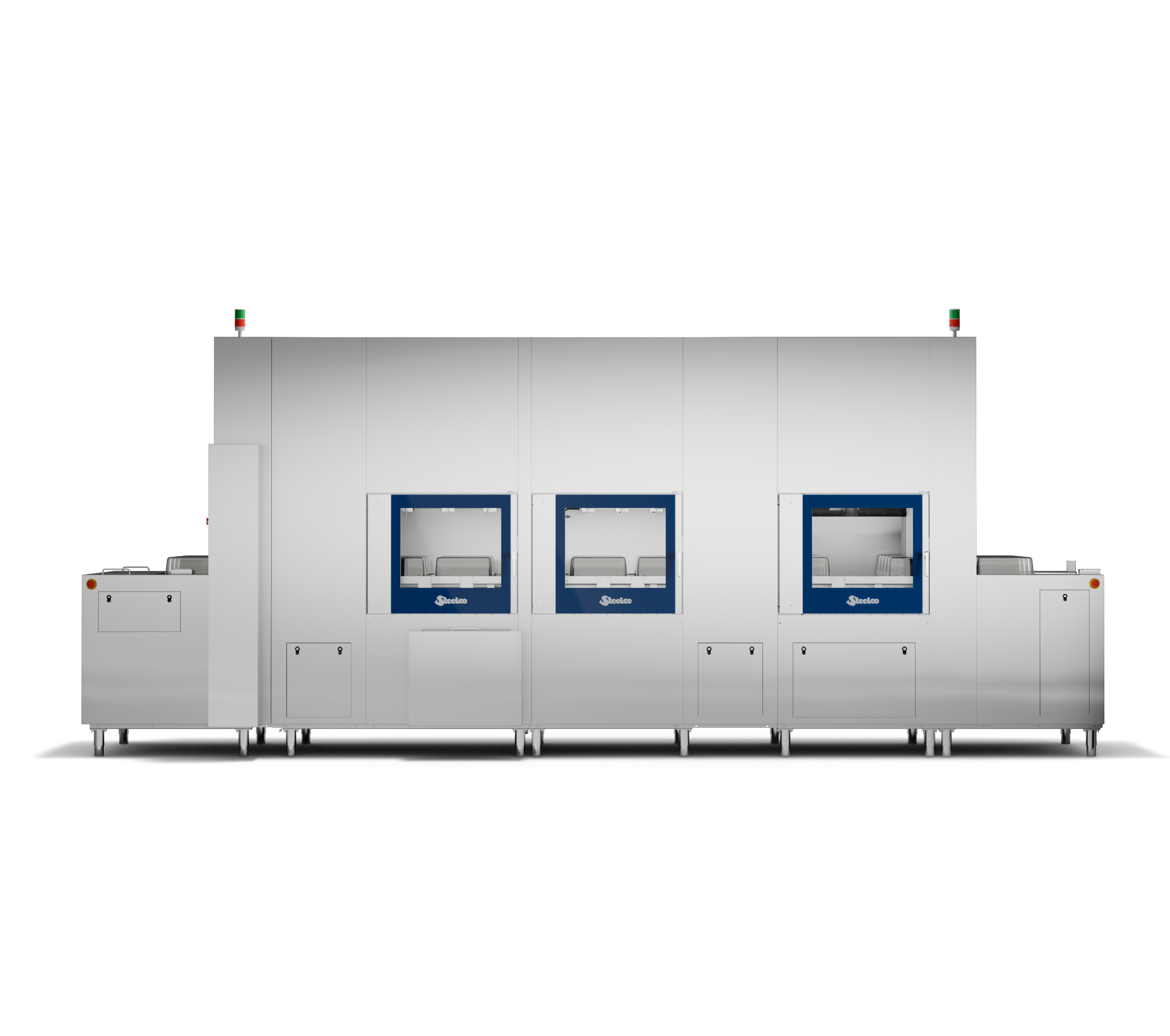

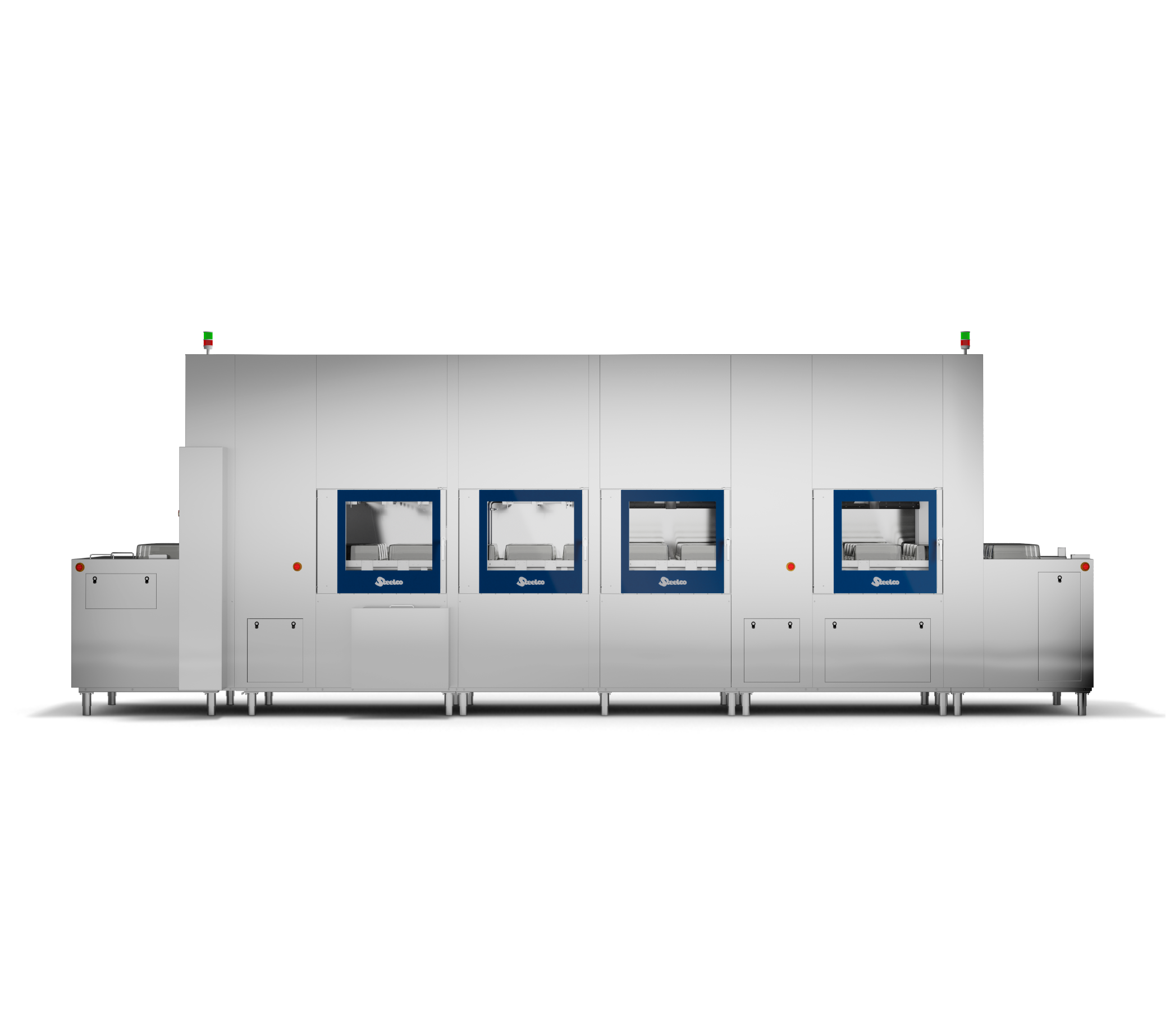

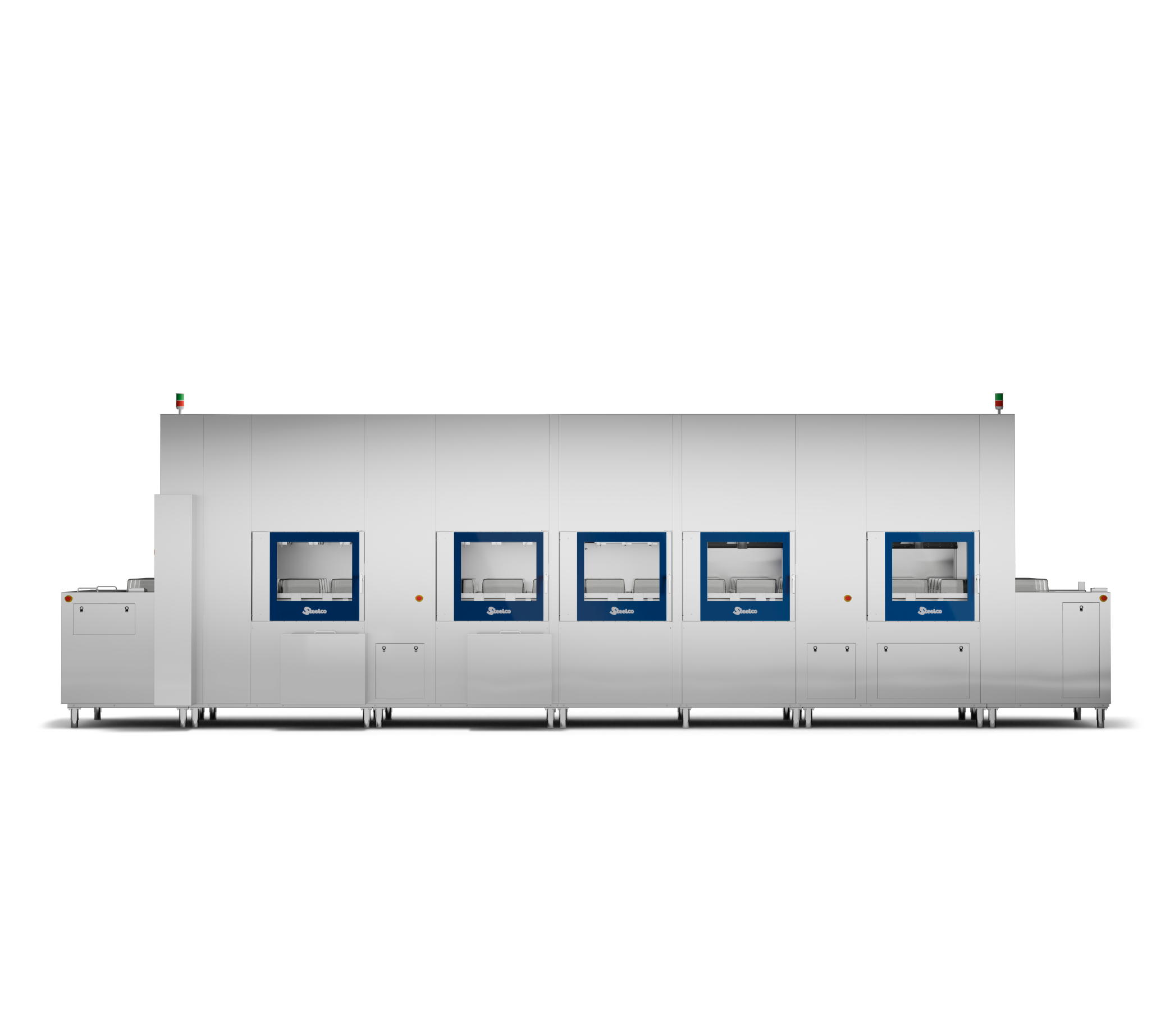

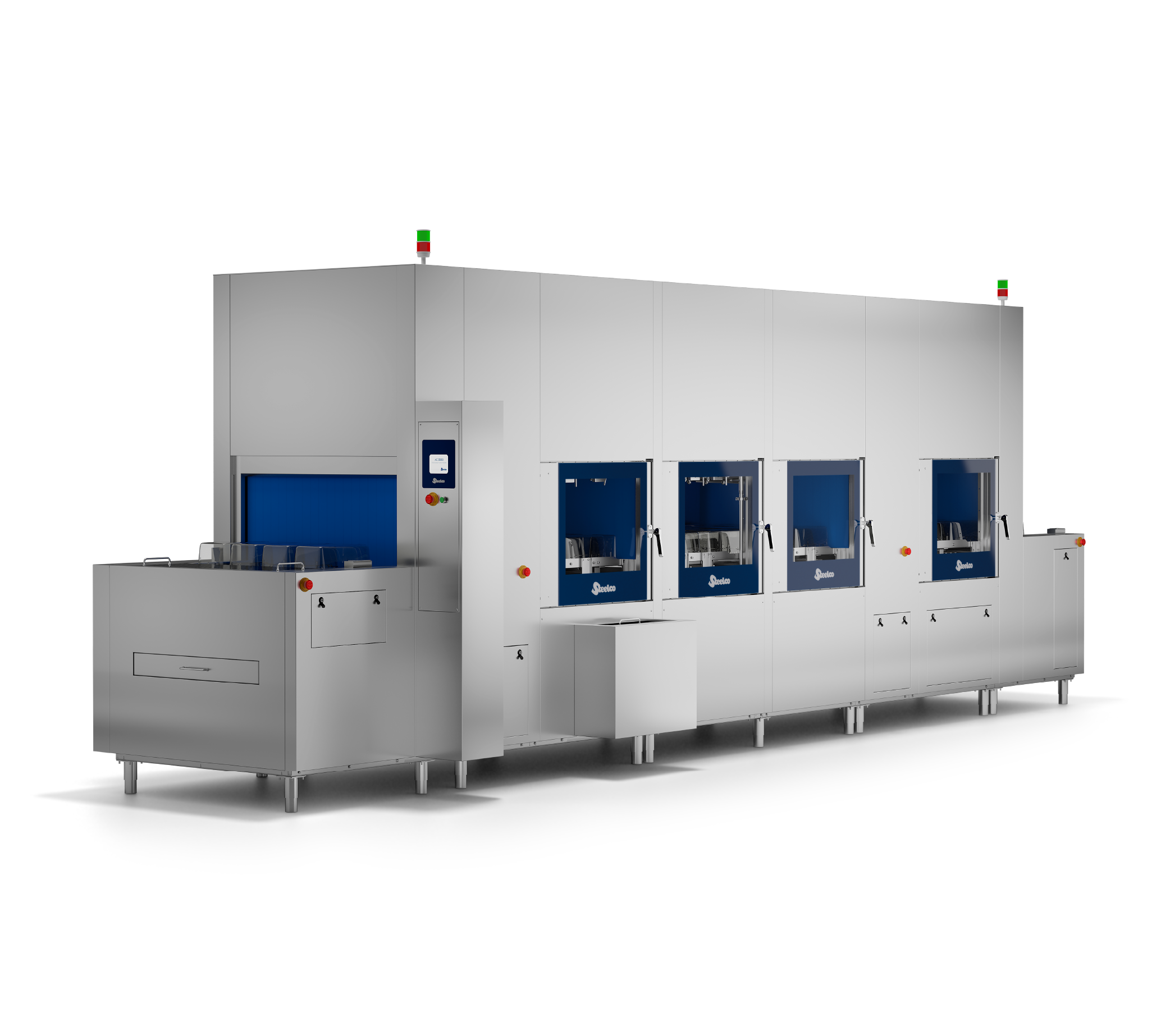

AC 3500

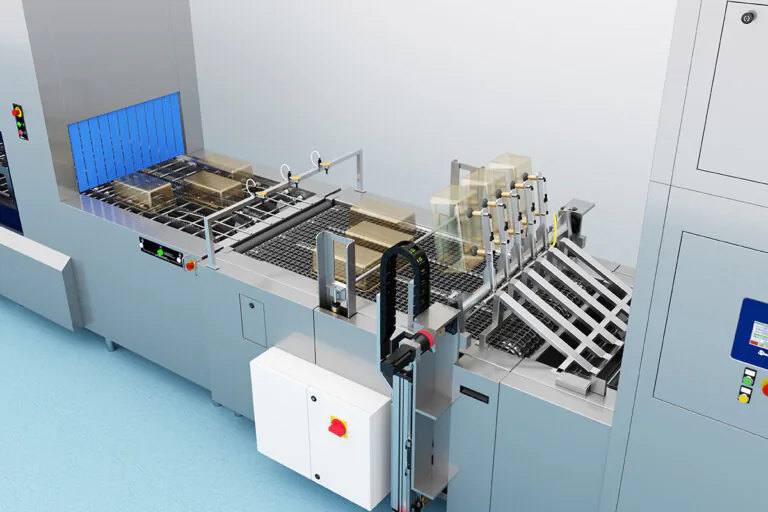

The combination of high pressure and flow rate ensures excellent washing and rinsing performance, with a productivity of up to 750 cages per hour. To support the growing demand for a compact system for the automatised handling of cages, the system can be integrated with robot technology for loading and unloading procedures.

Our AC 3500 offers an integrated and flexible solution composed of separate modules with dedicated functions – loading, pre-wash, acid/Alkaline wash, rinse and final rinse, drying, and unloading – to wash almost all the cage types available on the market and used in animal research laboratories. Modules can be added or removed for customised solutions. All the modules are available in the 900mm / 36″, 1100mm / 44″, and 1200mm / 48” transport belt width.

Key Features

-

Hygienic Design

High-quality AISI 316 L chamber and doors combined with AISI 304 external body for long-term reliability and maximum cleanliness

-

High Productivity

Outstanding washing and rinsing performance, with a productivity of up to 750 cages per hour

-

Customisation

All the modules are available in the 900mm / 36″, 1100mm / 44″, and 1200mm / 48” transport belt width

-

Cleaning Efficiency

Spray arms and separate rinsing circuit. Dedicated water jets for a high-temperature final rinse

-

Even Hot Air Distribution

The design of the air circuits allows a uniform air distribution inside the drying chamber

-

Intuitive Control System

Industrial PLC with user-friendly touch screen HMI, allowing for 65 programming options

Certifications

- ISO 9001 Certified Quality System. In addition, our products are subject to rigorous quality control systems and inspections. This coupled with continuous training of our technically specialised personnel ensures the best in class product solutions and support.

Configurations

Model | Length (mm) | Configuration Module | Enquire |

|---|---|---|---|

| AC 3500/A | 4500 | Loading station | Washing | Rinse | Unloading station | |

| AC 3500/B | 6000 | Loading station | Washing | Rinse | Standard drying | Unloading station | |

| AC 3500/C | 7000 | Loading station | Washing | Rinse | Long drying | Unloading station | |

| AC 3500/D | 7500 | Loading station | Pre-washing | Washing | Rinse | Standard drying | Unloading station | |

| AC 3500/E | 8500 | Loading module | Pre-washing module | Washing module | Rinse module | Load drying module | Unloading module |

Thank you for requesting a quote. A member of our team will be in touch shortly.

Thank you for requesting a quote. A member of our team will be in touch shortly.