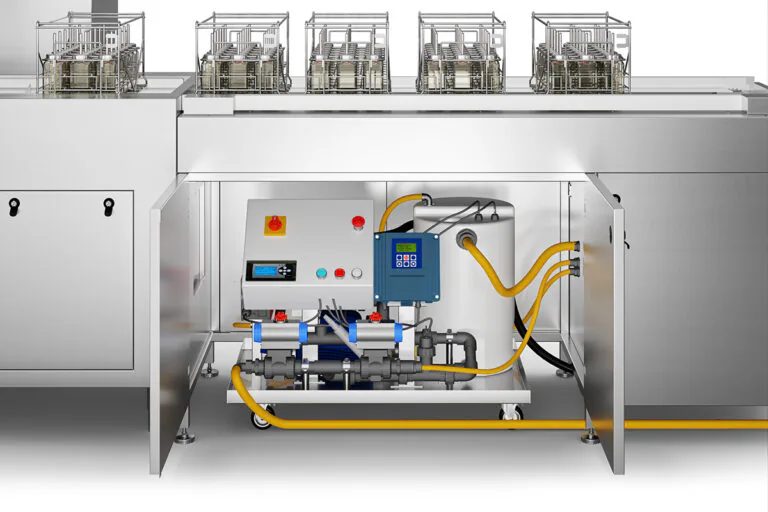

MITO FBS

Our MITO FBS is a modular system and can be configured with multifunctional loading and unloading tables and accessories. High-quality stainless steel AISI 316L chamber guarantees long-term reliability and cleanliness. The independent washing and rinsing system, with disinfection by rinsing at 85°C / 185F, ensures optimal cleaning and disinfection.

Key Features

-

Design and Safety

Chamber, boiler tank, washing and rinsing circuits made in high-quality stainless steel AISI 316L (DIN 1.4404) for long-term reliability and optimal cleanliness

-

Effective sanitisation

Individual nozzles for full bottles coverage during the wash and rinse cycles. Efficient sanitisation by rinsing at 85°C

-

High Performance Cleaning

Independent washing and rinsing system for optimal cleaning performance

-

Automatic detergent dosing

Automatic detergent dosing via peristaltic pump providing precise addition of liquid chemical agent

-

Process quality

Separate PT1000 temperature probes for sump and boiler water temperature control and water level sensor to control chamber water level and prevent overflow

-

Control system

Microprocessor control system with RS232 port for external connection. LCD Display control panel, with up to 40 programs capacity

Certifications

- Meets European requirements EN 61010-1, EN 61010-2-040, EN 61326-1

Configurations

External Dimensions – Hood closed – WxDxH(mm) | External dimensions – Hood open – WxDxH (mm) | Enquire |

|---|---|---|

| 650 x 700 x 1465 | 650 x 700 x 1865 |

Thank you for requesting a quote. A member of our team will be in touch shortly.

Thank you for requesting a quote. A member of our team will be in touch shortly.