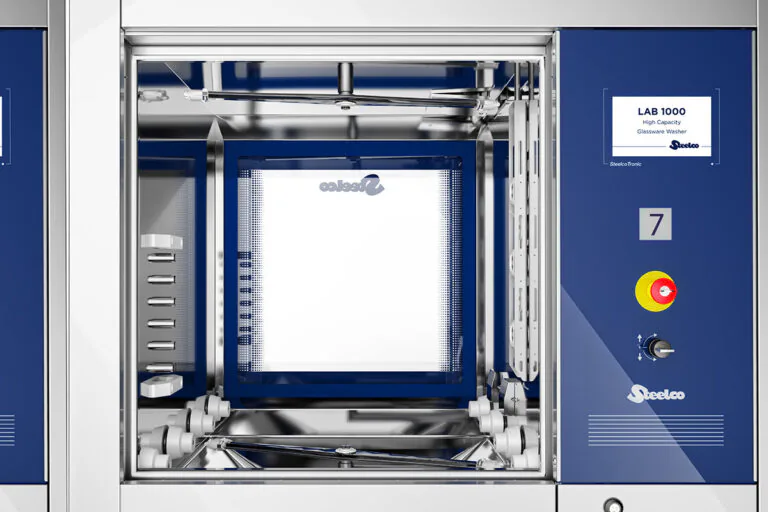

LAB 1000 High-Capacity Glassware Washer

Our LAB 1000 ensures outstanding washing and drying results of all laboratory glassware thanks to the accurate distribution of the air on all the chamber zones and on the washing cart levels. A built-in pre-heating tank is available upon request to perform faster washing cycles. In this configuration the washer can perform a complete cycle in less than 40 minutes. The HEPA 14 filtered forced air drying system helps achieve complete drying of your glassware’s exterior and interior.

The washing cart system is developed starting from a base injection washing cart that can fit up to 4 removable injection cassettes on 2 levels. The upper levels can be removed depending on the height of the loaded glassware. Loading and unloading washing carts operations can be done at an ergonomic height by using manual or automatic single loading/unloading transfer trolleys.

Home / Laboratory Glassware Washers / LAB 1000 High-Capacity Glassware Washer

Click to see full view

Click to see full view

Hover to zoom

LAB 1000 High-Capacity Glassware Washer

Our solutions are trusted by industry leaders for critical processes in Infection Control & Life Science sectors:

Key Features

-

High and Flexible Capacity

Washing and drying system on up to 3 independent levels. The unit is able to treat carboys and large glassware up to a height of 605 mm / 23.62″

-

Process Quality

Flow meter for accurate volumetric dosing of chemicals and a conductivity sensor for measuring of the conductivity value during the final rinse phase are available upon request

-

Drying Efficacy

Built-In HEPA 14 filtered forced air drying system ensuring the complete internal and external drying of all the glassware. Adjustable time and temperature settings for the optimisation of cycle duration and energy consumption

-

Easy Access to Chemicals

Hinged door for easy access to storage of chemical tanks – up to three 10 lt / 2.64 Gal US

-

7″ User-Friendly HMI

Industrial PLC with intuitive 5.7″ touch-screen HMI, allowing for 65 programming options

-

Full Traceability

RS 232 port for printer connection, Ethernet connection to general data system to monitor and validate the washing cycles and/or the data storage. Integrated printer and barcode reader available as options

Certifications

- Steelco Laboratory glassware washers comply with the current European directives and standards as follow: 2006/42/EC, 2014/35/EU, 2014/30/EU, and 2011/65/EU Directives, EN 61010-1, EN 61010-2-040, EN 61326-1, EN ISO 15883-1 current standards

Configurations

Overall Dimensions WxDxH (mm) | Chamber Volume (L) | Basket Volume (L) | Enquire |

|---|---|---|---|

| 1100 x 960 x 1940 | ~500 | ~350 |

Downloads

Steelco Glassware Washers High Capacity

Download

Thank you for requesting a quote. A member of our team will be in touch shortly.

Thank you for requesting a quote. A member of our team will be in touch shortly.