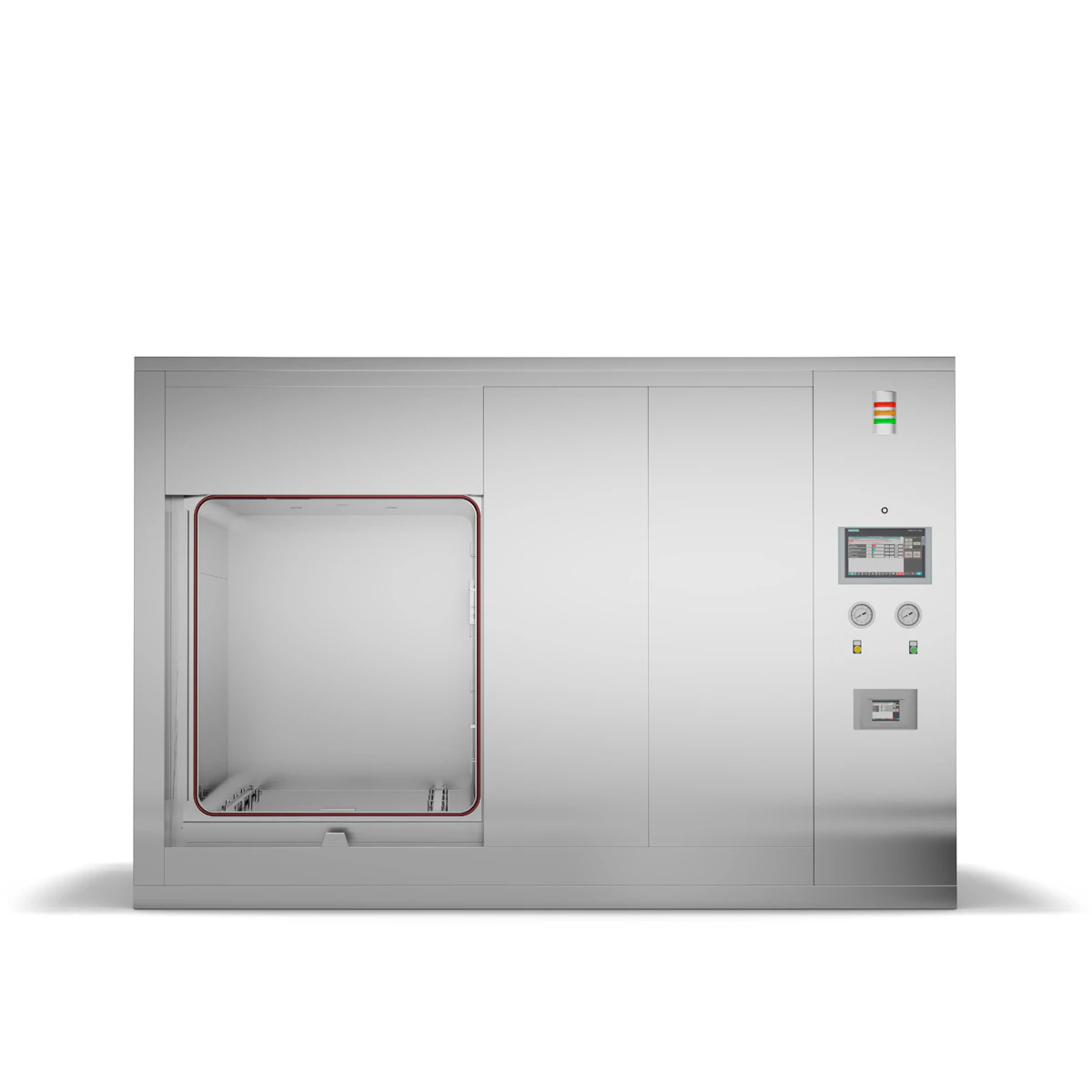

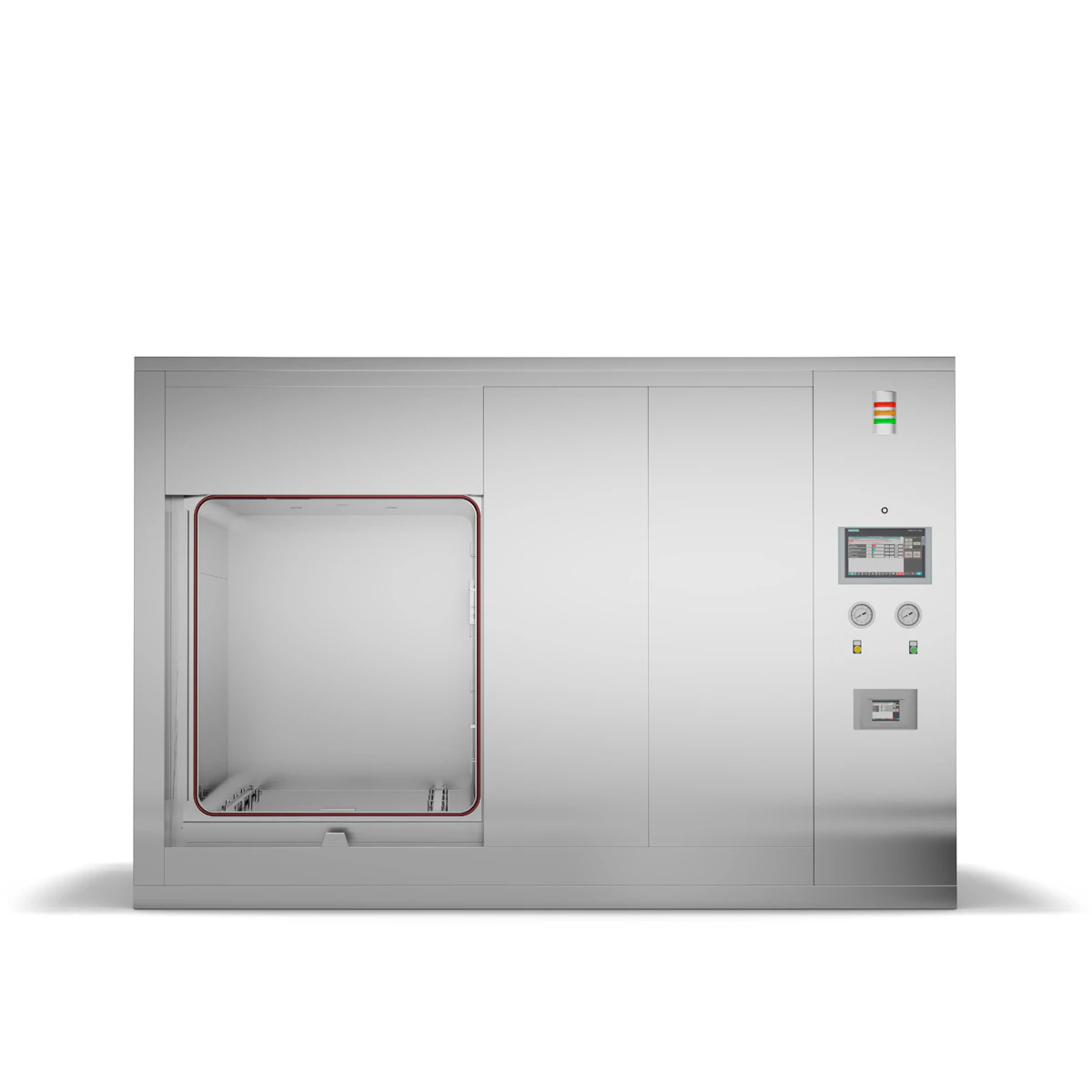

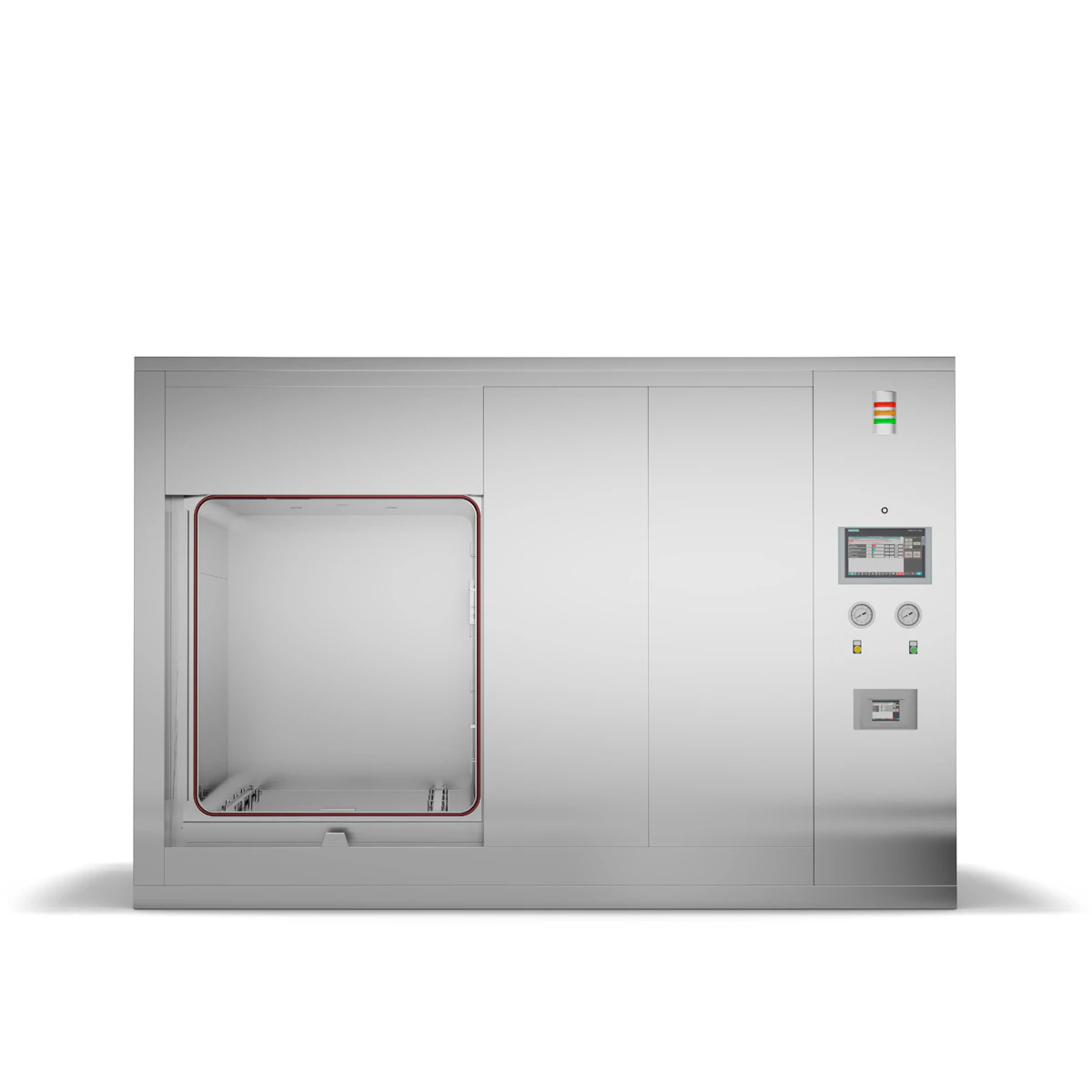

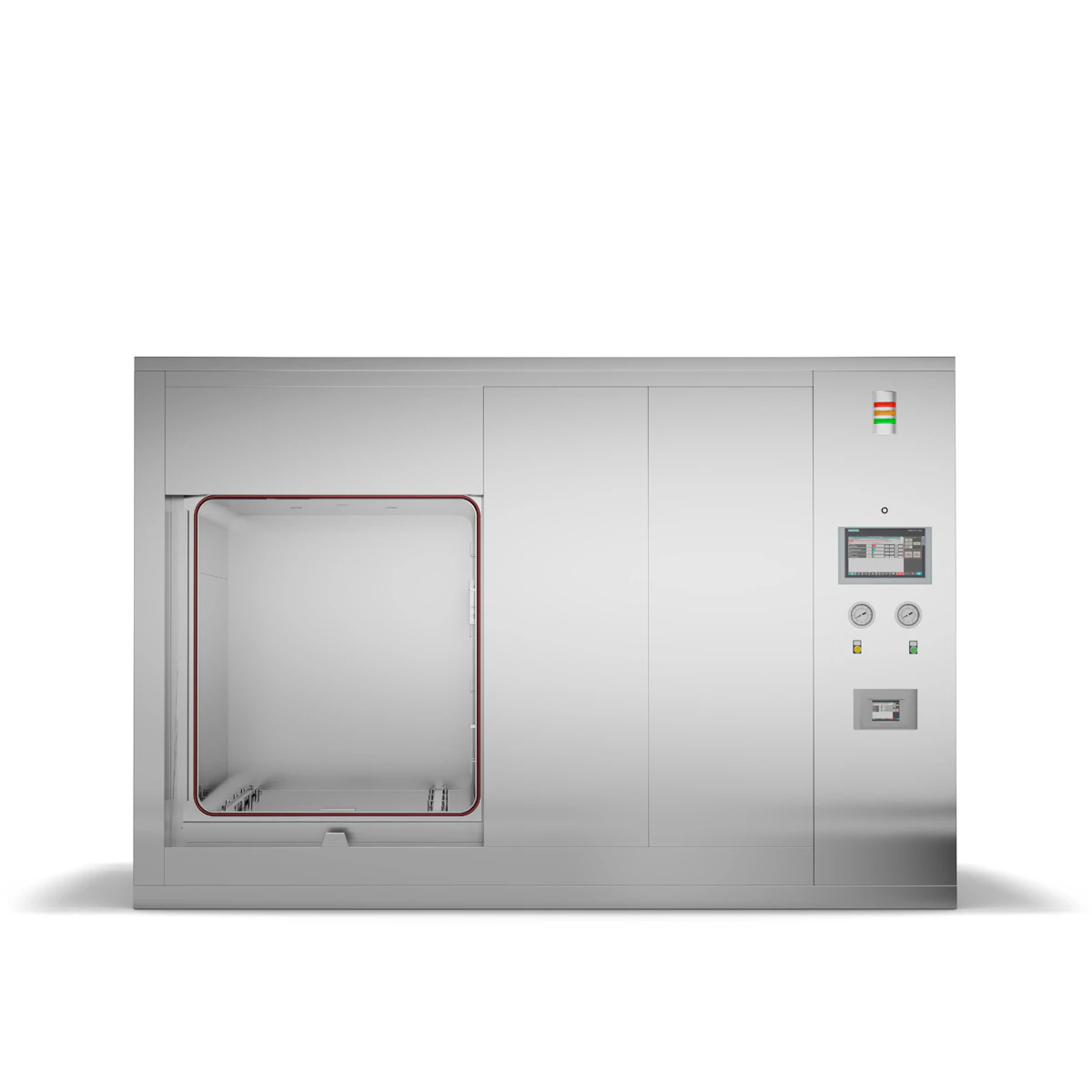

AV Series Pharma-Grade Saturated Steam Sterilisers

With over 30 years of engineering excellence, Steelco provides a comprehensive range of units for the sterilisation of vials, bottles, glassware, fabrics, machine parts, filters, rubber components, and both sealed and vented containers. Using clean/pure saturated steam, the AV Series ensures uniform sterilisation results with a focus on cycle efficiency, energy savings, and throughput optimisation. Additionally, these systems are manufactured, validated, and documented in accordance with the most rigorous international regulations to support customer compliance with current Good Manufacturing Practices (cGMPs).

Home / Pharmaceutical Sterilisers / AV Series Pharma-Grade Saturated Steam Sterilisers

Click to see full view

Click to see full view

Click to see full view

Click to see full view

Click to see full view

Click to see full view

Click to see full view

Click to see full view

Click to see full view

Click to see full view

Click to see full view

Hover to zoom

AV Series Pharma-Grade Saturated Steam Sterilisers

Our solutions are trusted by industry leaders for critical processes in Infection Control & Life Science sectors:

Key Features

-

Customisable Chamber Sizes

Chamber volumes from 195 to 10,000 litres (7 to 353 cu ft), with custom sizes available upon request.

-

Advanced Construction & Materials

High-quality AISI 316L stainless steel chamber and jacket with dimple-welded full-jacketed insulation for rapid and uniform heat transfer. Chamber is self-draining, cylindrical or rectangular in shape, and fully insulated with ceramic material.

-

Flexible Configuration

Available in single or pass-through versions with sliding or hinged doors. Floor-mounted or pit-mounted configurations available, with right/left or shared technical areas.

-

Optimised Sterilisation Cycles

Designed to reduce time and energy consumption. Standard and custom recipes can be developed and configured for maximum flexibility and process efficiency.

-

User-Friendly Automation

Fully integrated HMI or SCADA systems using Siemens or Allen-Bradley platforms. Compliant with FDA 21 CFR Part 11, EU Annex 11, and GAMP 5 guidelines. MES and IS system integration supported.

-

Remote Access

Built-in VPN router allows secure remote diagnostics and service access without requiring an on-site technician, enhancing uptime and lowering maintenance costs.

-

Safe & Validated Operation

Includes front-side validation ports for easy testing, optional drain cooling systems, and compatibility with isolation technology and HPV generators for critical applications.

-

Long-Life Door Seal

Single-piece silicone “Dove Tail” pneumatic gasket designed for a minimum 4-year lifespan.

-

Non-Proprietary Parts

Built with globally available, non-proprietary components to ensure flexible and cost-effective maintenance.

Certifications

- cGMP | GAMP 5 | FDA 21 CFR Parts 11, 211, 820 | Eudralex | ASME BPE | PDA Technical Reports | ISPE Guidelines | European and US Pharmacopeia | UL and CSA (on request)

Configurations

Chamber Volume (L) | Door Options | Construction Materials | Layout Options | Automation & Control | Optional Features | Enquire |

|---|---|---|---|---|---|---|

| 195 – 10 000L | Hinged or horizontal sliding; single or double-door pass-through | AISI 316L stainless steel chamber and jacket | Ceramic insulation | ASME BPE-compliant AISI 316L piping with tri-clamp fittings | Floor- or pit-mounted installation | Integrated or remotely located electrical cabinet | Configurable technical access sides (left/right/shared) | Siemens or Allen-Bradley PLC/HMI | HMI/SCADA interfaces | Remote service access via VPN | Drain cooling system | Air detector (EN 285 compliant) | Integration with hydrogen peroxide generators or isolators |

Thank you for requesting a quote. A member of our team will be in touch shortly.

Thank you for requesting a quote. A member of our team will be in touch shortly.