In the Pharmaceutical manufacturing sector, contamination control is a non-negotiable. From aseptic compounding to sterile testing, every step requires precision, reliability, and compliance. That’s why Sychem, in partnership with Ortner, a global leader in cleanroom solutions, delivers best-in-class technologies backed by local expertise and support.

Introducing Ortner: Pioneers in Cleanroom Solutions

Since 1985, Ortner has been at the forefront of cleanroom technology, combining cutting-edge innovation with deep expertise. Their solutions create microbiologically and particle-clean environments that protect people, products, and the environment from contamination risks. This commitment has earned Ortner the title of “SME World Market Leader”, making them a trusted partner in industries with heightened cleanliness and sterilisation standards.

Expertise Across Hygiene-Critical Industries

Ortner tailors their cleanroom technologies to meet distinct and definitive needs across varied sectors:

- Pharmaceuticals & Biotechnology: From research labs to large-scale production, including BSL labs and in-vivo research

- Medical Sector: Institutional pharmacies, hospitals, and nursing homes

- Food Industry: Hygienic solutions for dairy, bakeries, meat processing, and more

- Industrial Manufacturing: Precision cleanrooms for electronics and advanced manufacturing

Why Sychem Partnered with Ortner

Sychem shares Ortner’s vision for safety, efficiency, and sustainability in contamination control. Together, we provide end-to-end cleanroom and isolator solutions that meet the highest regulatory and quality standards:

- Shared Values: Commitment to advancing technologies that safeguard health, safety, and the environment

- Innovative Synergies: Ortner’s pioneering systems complement Sychem’s expertise in sterilisation and decontamination

- Comprehensive Solutions: Ortner’s extensive product range enables tailored solutions for diverse customer needs

Ortner’s Range of Solutions

Ortner’s portfolio addresses every facet of cleanroom and Pharmaceutical manufacturing:

- Isolators: Modular systems for aseptic and toxic processes, including robotic solutions

- RABS Systems: Advanced barrier systems for enhanced production quality

- Decontamination Locks: Automated airlocks, including compact H2O2 solutions

- Material Transfer Hatches: Active, passive, and combined options for safe cleanroom transfer

- Personnel Locks: Showers and airlocks for sterile entry

- UVC+ Airlock: a modular, automated system that combines air showers with ultraviolet-C (UVC) light for particulate removal and microbiological decontamination of materials in cleanroom environments.

- Laboratory Equipment: Custom solutions like transport systems, racking, and safety cabinets

- H2O2 Gas Generators & Distribution: High-performance fumigation for mobile or stationary setups

- CH₂O Gas Generators: Formaldehyde-based decontamination for specialised applications

- Room & Line Protection Systems: Airflow solutions for optimal product safety

- Spot Protection Systems: Targeted airflow for precise contamination control

By combining Sychem’s local expertise with Ortner’s world-leading technologies, customers gain access to trusted, turnkey solutions for Pharmaceutical and critical manufacturing environments.

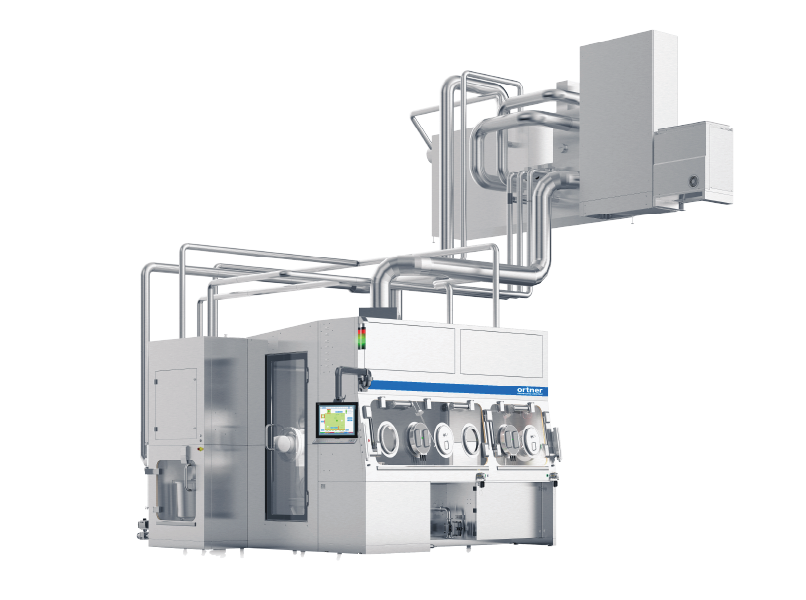

A Closer Look at The IsoLine Range

- Closed modular systems for aseptic production of highly sensitive products

- Positive pressure operation (10–100 Pa) prevents contamination ingress

- Fully automatic H2O2 bio-decontamination (LOG6 germ reduction)

- Integrated environmental monitoring: Laminar flow, pressure, temperature, humidity, particle counts

- Ergonomic design with height-adjustable sit-stand workstation, intuitive touchscreen interface

- Flexible material transfer offering quick-acting airlocks on left or right for loading/unloading

- Negative pressure operation (-10 to -100 Pa) ensures safety when handling toxic substances

- Complete separation of operator and product via glove interventions and airflow control

- Automatic H202 bio-decontamination with integrated gas generator and logging

- Advanced environmental monitoring for pressure, humidity, temperature, and particle counts

- Customisable interior chamber equipment for precision dosing, weighing, or mixing

Sterile Test Isolators

- Modular, closed systems for aseptic sterility testing

- Positive pressure and automatic bio-decontamination for GMP Class A compliance

- Integrated online particle and environmental monitoring for continuous quality assurance

- Ergonomic and flexible workspace design with height-adjustable workstation

Containment Isolators

- Negative pressure operation protects personnel during handling of powdered hazardous substances

- Automated WIP/CIP cleaning processes with fluorescence testing for cleanability

- Advanced monitoring systems for airflow, pressure, temperature, and humidity

- Ergonomic design ensures safe and comfortable operator interaction

Automated and Robotic Solutions

- Tailored AI-driven automation for specialised processes

- Full-service support from concept to implementation

- Integration with sterilisation and decontamination processes for end-to-end safety and compliance

Owing to this partnership, Sychem ensures that customers in the pharmaceutical manufacturing and critical industries can access:

- Globally leading cleanroom technology

- Locally delivered expertise and support

- Turnkey isolator and decontamination solutions

- Compliance with GMP, ISO, and Annex 1 standards

- Maximum safety for personnel, product, and environment

Together, we deliver trusted, end-to-end contamination control solutions, enabling manufacturers to maintain the highest standards of safety, efficiency, and operational excellence.