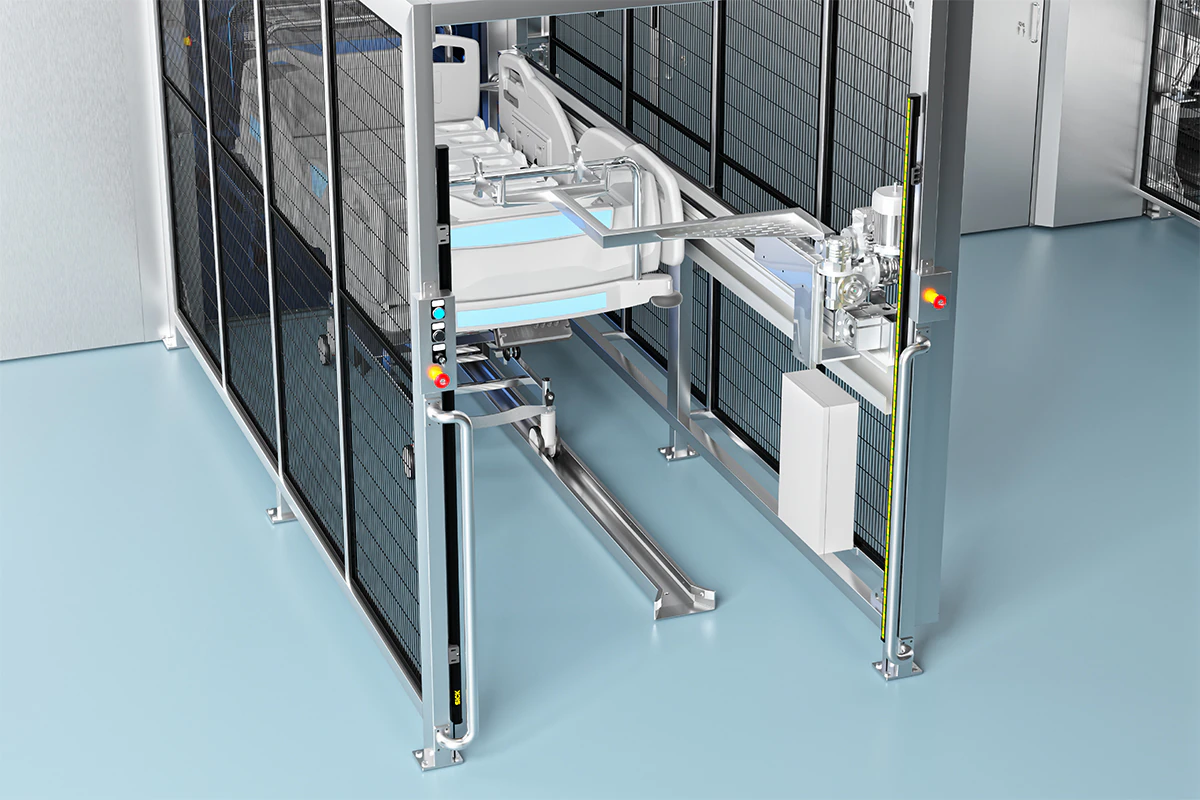

LC 80 BOT Wide Chamber Washer Disinfector

With our LC 80 BOT Washer Disinfector, you can choose two different chamber depths: the 2250 mm / 88.58″ and 3000 mm / 118.11″, according to your cleaning demand. The combination of high-flow recirculation pumps and high-speed blowers for forced air drying provides the washer with high-performance cleaning and thermal disinfection treatment with short cycle times ensuring high throughput.

Available as single door or double door pass-through versions, this latter version is suitable for barrier installation to reduce cross-contamination by separating dirty areas from clean ones. A PLC microprocessor with a user-friendly 7″ or 10″ colour touchscreen that supports operators. The control system allows for 65 programming options.

Home / Infection Control Washer Disinfectors / LC 80 BOT Wide Chamber Washer Disinfector

Click to see full view

Click to see full view

Hover to zoom

LC 80 BOT Wide Chamber Washer Disinfector

Our solutions are trusted by industry leaders for critical processes in Infection Control & Life Science sectors:

Key Features

-

Water Recycling

In addition to saving water, the LC 80 BOT’s efficient recovery system saves energy and chemicals. Depending on the configuration of the machine, it is possible to install more water and energy recovery systems, making the most of its capabilities.

-

Optimal Cleaning

Multiple horizontal oscillating pipes equipped with spraying nozzles on each washing chamber side ensure optimal wash surface coverage.

-

Effective Chemical Disinfection

Dedicated separated circuits for washing and rinsing for a high-quality process. Water and chemical recovery systems together with advanced technologies for water injection guarantee excellent results in a short time.

-

Smart Filtering System

Three-level water filtration system allows for the capture of residues during the recirculation of the washing filter thanks to flush self-cleaning final filter, thus avoiding the risk of clogging and protecting the recirculation point.

-

Drying Efficacy

Built-In HEPA 14 filtered forced air drying system providing total removal of the rinse water residues. Warm air inside the chamber is homogeneously distributed for fast and efficient drying.

-

Traceability

USB port printer connection for machine data backup. Remote monitoring and data management with the optional SteelcoData traceability software.

Certifications

- CE certified machine following the 93/42/EEC directive.

- Thermal disinfection version EN ISO 15883-1/2 compliant.

- Chemical disinfection version EN ISO 15883-1/6 compliant.

Configurations

Model | Dimensions WxDxH (mm) | Washing Chamber Capacity | Enquire |

|---|---|---|---|

| 2250 mm Chamber Version | 2900 x 2550 x 2410 | Up to 28x STU | |

| 3000 mm Chamber Version | 2900 x 3300 x 2410 | Up to 42x STU |

Downloads

Steelco LC Series Trolley Washers

Download

Thank you for requesting a quote. A member of our team will be in touch shortly.

Thank you for requesting a quote. A member of our team will be in touch shortly.