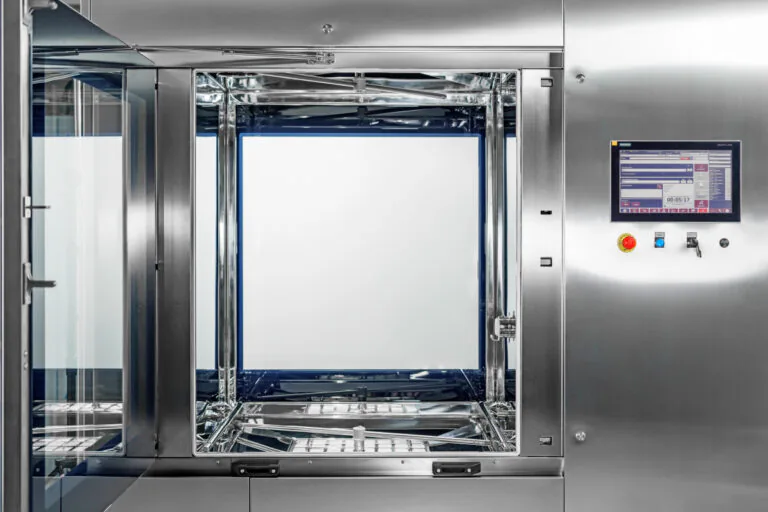

DS Optima PH Parts Washer

Home / Pharmaceutical Cleaning Systems / DS Optima PH Parts Washer

Click to see full view

Click to see full view

Click to see full view

Click to see full view

Hover to zoom

DS Optima PH Parts Washer

Our solutions are trusted by industry leaders for critical processes in Infection Control & Life Science sectors:

Key Features

-

Compact & Cost-Effective

Designed for maximum cleaning power with minimal space requirements and fast-track delivery timelines.

-

GMP-Compliant

Fully aligned with global GMP standards including cGMP, FDA 21 CFR Part 11, and EU Annex 11.

-

Unrivalled Cleaning & Drying

Validatable results with a high-performance hydraulic system and variable temperature-controlled drying.

-

Self-Cleaning System

Prevents cross-contamination with fully integrated chamber and pipework cleaning at every cycle stage.

-

Flexible Configuration

Available in single-door or passthrough double-door with left or right technical area placement.

-

Easy Maintenance & Remote Support

User-accessible components, non-proprietary parts, and VPN-enabled diagnostics reduce downtime and support costs.

-

Custom Racking & Cycle Development

Tailored racks and recipes for deep, uniform cleaning and drying of every item and cavity.

Certifications

- Designed and validated according to current Good Manufacturing Practices (cGMP) | Fully compliant with FDA 21 CFR Part 11 | Developed according to ISPE GAMP© guidelines | Uses FDA-approved (21 CFR Part 177) gaskets and materials

Configurations

Chamber Volume (L) | Overall Dimensions (mm) | Doors | Material | Surface Finish | Drying System | Enquire |

|---|---|---|---|---|---|---|

| 1200L | 2200x1150x2500mm | Single or passthrough hinged glass | AISI Stainless Steel (electropolished) | Ra<0.51 µm (Ra < 0.38 µm upon request) | HEPA filtered air with variable temperature control |

Thank you for requesting a quote. A member of our team will be in touch shortly.

Thank you for requesting a quote. A member of our team will be in touch shortly.