Aseptic Isolators

Home / Pharmaceutical Isolators / Aseptic Isolators

Click to see full view

Click to see full view

Click to see full view

Click to see full view

Hover to zoom

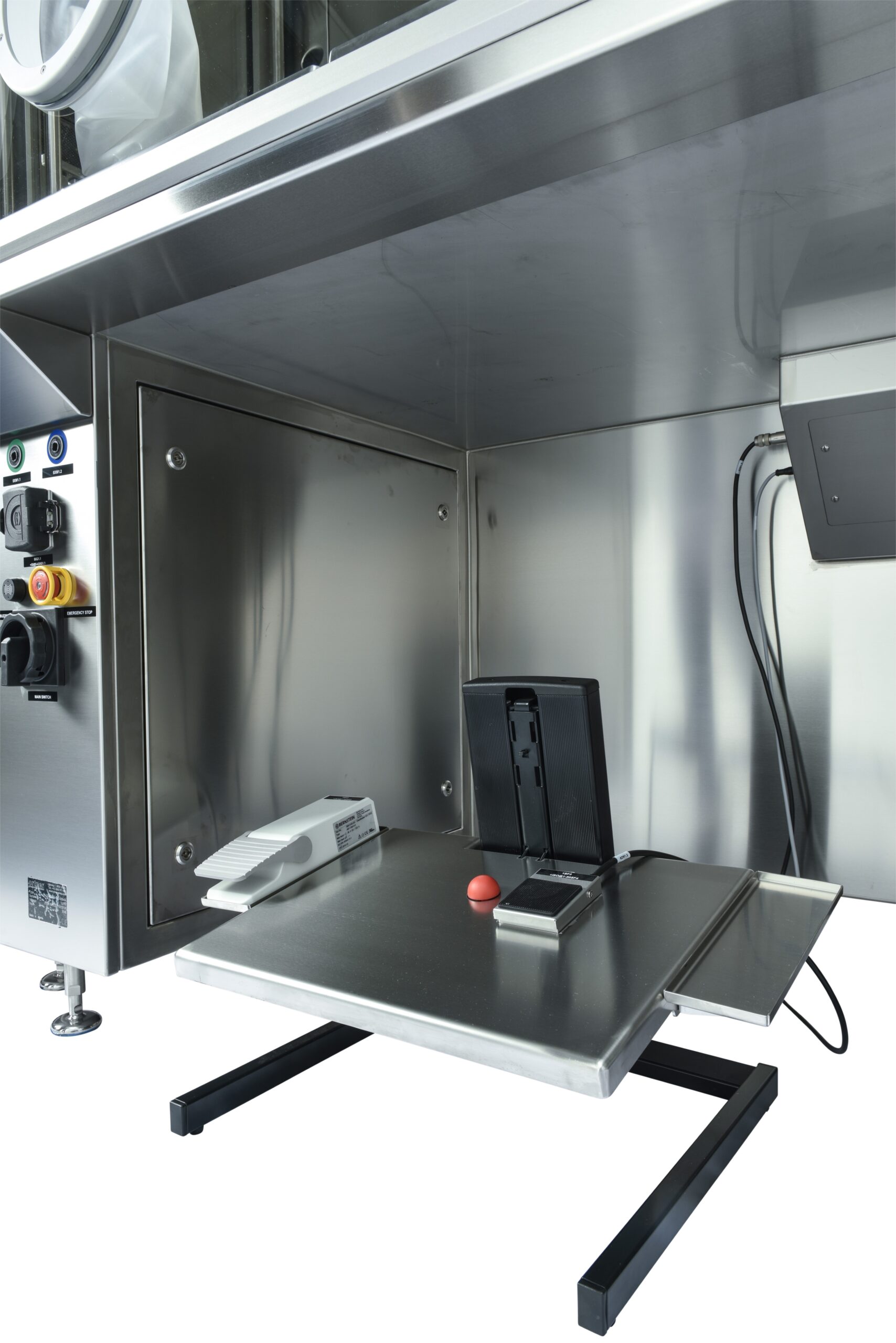

Aseptic Isolators

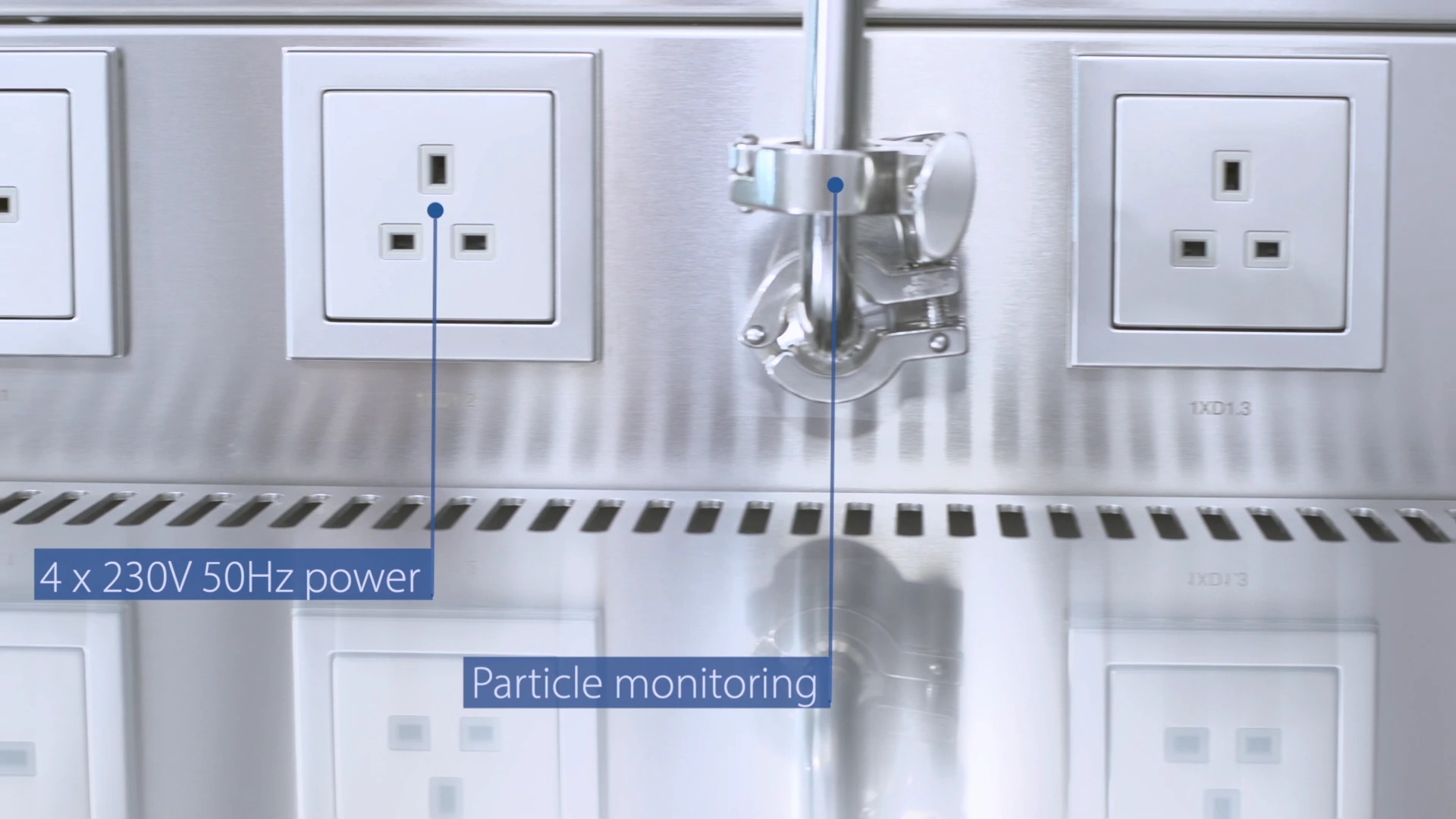

Continuous Particle Monitoring

Particle monitoring is a critical parameter in GMP monitoring and is used to monitor air purity. Ortner isolators are equipped with a fully integrated, user-friendly online particle measurement system for 0.5 μm and 5.0 μm particle sizes. The monitoring is active during production operation, with particle concentrations measured continuously throughout the entire production process.

Configurations

Technical Specifications | Values |

|---|---|

| Cleanroom Class | ISO 5/A (chamber); ISO 8/D or better (installation site) |

| Weight | 900 kg (2-glove model) / 1200 kg (4-glove model) |

| Electrical Supply | 3 x 400V / 50 Hz / 8 kW |

| Compressed Air | H14 filtered; 6 bar at 400 L/min |

| Airflow Velocity | 0.3 – 0.45 m/s (adjustable) |

| Noise Level | < 60 dB(A) |

| Integrated H2O2 Gas Generators | ISU Compact; LOG6 decontamination; injection rate 1-10 g/min |

| Particle Monitoring | Online system for 0.5 μm & 5.0 μm with continuous logging |

| Isolator Control System | Siemens S7-1500 PLC with 9” touchscreen interface |

Customisable Options

- Automated glove testing & logging

- Additional airlocks with bio-decontamination

- Integrated temperature & humidity monitoring

- Remote maintenance access & audit trail

- Intercom system with surveillance camera

- Fully adjustable isolator height

- Additional RTP ports & electrical connections

Downloads

Pharmaceutical The Complete Solution

Download

Case Studies

Featured Posts

Thank you for requesting a quote. A member of our team will be in touch shortly.

Thank you for requesting a quote. A member of our team will be in touch shortly.