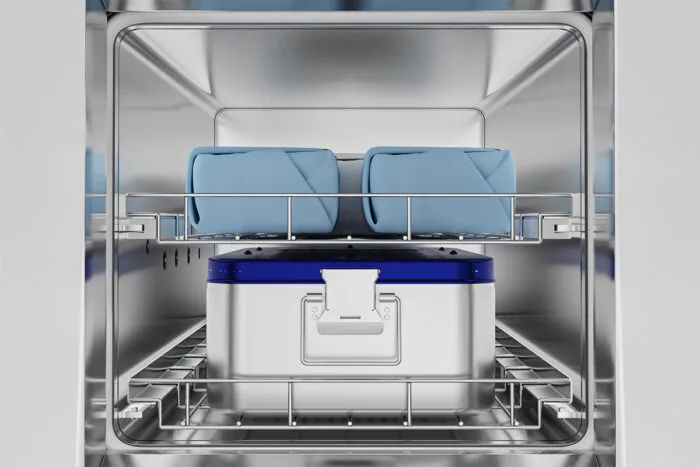

PL 130 Low Temperature High Capacity Steriliser

Available as single door or double door versions, it is equipped with an automatic space-saving sliding door. Sychem’s PL 130 is controlled by a PLC digital microprocessor with a 10″ colour touch screen HMI. Loading and unloading operations can be done at an ergonomic height. The loading height is ergonomically placed at 920 mm / 36.22″.

Home / Infection Control Sterilisers / PL 130 Low Temperature High Capacity Steriliser

PL 130 Steelco steriliser front view

Click to see full view

PL 130 Steelco steriliser side view

Click to see full view

Hover to zoom

PL 130 Low Temperature High Capacity Steriliser

PL 130 Steelco steriliser front view

PL 130 Steelco steriliser side view

Our solutions are trusted by industry leaders for critical processes in Infection Control & Life Science sectors:

Key Features

-

Small Footprint

Similar features, benefits, and performances of the larger capacity PL models with the most compact footprint on the market regarding load capacity.

-

Excellent Penetration

Excellent penetration into hollow instruments: Lumens: Ø ≥ 0.5 length ≤ 2200 mm, with single, double, and triple channels.

-

Immediately Available

The models of the PL series are all Plug & Play, ready to be started quickly in any location.

-

Shelves Position Configurable

Loading flexibility thanks to chamber modularity with semi-extractable shelves and a perfect range of accessories, including baskets and inserts.

-

Environmental Sustainability

Hydrogen Peroxide emissions are up to 70 times lower than the most restrictive guidelines thanks to the triple safety system for reducing H2O2 release: plasma generator, catalysed converter, and an active carbon filter.

-

RFID or Barcode Recognition

All the devices have the option of the Barcode or RFID scanner for easy and quick recognition of the operator and the load.

Certifications

- European Directive for Medical Devices: 93/42/EEC and its revised versionsn

- Technical norms and standards: EN ISO 14937 (ANSI/AAMI) | EN ISO 14971 | UNI EN ISO 17665-1 | IEC EN 61010-1 | IEC EN 61010-2-040 | EN 62366-1| IEC EN 61326-1

Configurations

Door Version | Overall Dimensions (mm) | Chamber Volume (L) | Enquire |

|---|---|---|---|

| Single | 642 x 920 x 1630 | 143 | |

| Double | 642 x 990 x 1630 | 148 |

Thank you for requesting a quote. A member of our team will be in touch shortly.

Thank you for requesting a quote. A member of our team will be in touch shortly.