PWD 86 Series Instrument Washer Disinfector

In our PWD 86 series, you can choose between two sizes to optimise your CSSD layouts – with 900 mm / 35.44″ or 1150 mm / 45.28″ width. The two configurations share the same main features and performance, and they both conveniently use the same wash racks and modules, ensuring a smooth workflow. In addition, Steelco has developed the new patented “Power Pulse Cleaning” technology to improve the cleaning of MIS instruments that are difficult to reprocess, thus minimizing or eliminating any need for manual pre-cleaning.

Home / Infection Control Washer Disinfectors / PWD 86 Series Instrument Washer Disinfector

Steelco PWD 86 front view

Click to see full view

Steelco PWD 86 side view

Click to see full view

Hover to zoom

PWD 86 Series Instrument Washer Disinfector

Steelco PWD 86 front view

Steelco PWD 86 side view

Our solutions are trusted by industry leaders for critical processes in Infection Control & Life Science sectors:

Key Features

-

Flexible Solutions

Available in 900 mm and 1150 mm width models sharing the same wash racks and modules.

-

Space Saving Concept

Fewer racks and modules allow you to save space in your busy CSSD and still get the perfect results you need.

-

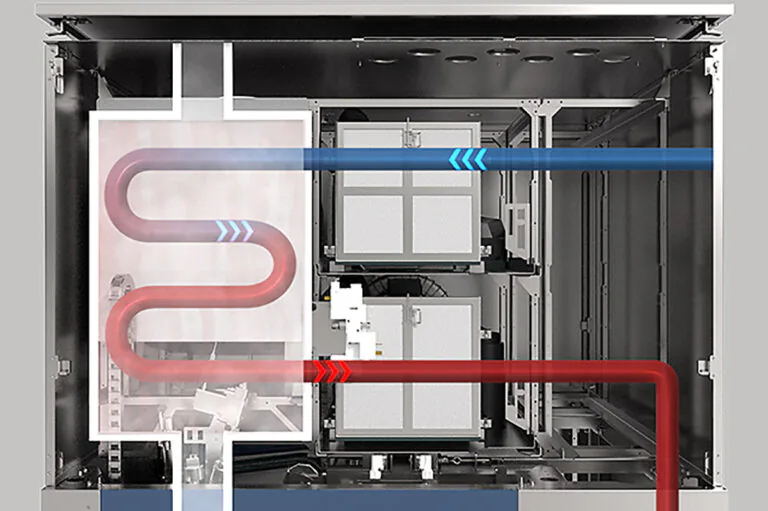

Adaptive Speed Washing

A variable speed pump system allows the adjustment of water pressure and flows according to the amount and type of load and the cycle phase (clean, rinse, or disinfection).

-

Dynamic Water Loading

Proper water temperature, pressure and flows thanks to controlled water inlets and a variable speed pump. A second pump is fully dedicated to the chamber washing arms.

-

User Friendly Large HMI

7‘‘colour touch displays are integrated into the glass front panel of the washer and installed on both loading and unloading sides.

-

Full Traceability

Full history cycle traceability, compatible with Steelco Data Pro. Ethernet Port for network communication. Integrated printer is available as an option.

Certifications

- Steelco PWD 8626 and PWD 8628 washer disinfectors are designed and constructed to comply with the latest guidelines: 93/42/ EEC and s.m.i, EN ISO 15883-1/2, CEN ISO/TS 15883-5, EN ISO 14971, IEC EN 61010-1, IEC EN 61010-2-040, EN 61326-1, EN 62304.

Configurations

Model | Overall Dimensions (mm) | Chamber Volume (L) | Load Capacity | Enquire |

|---|---|---|---|---|

| PWD 8626 | 900x990x2500mm | 351L | Up to 18 DIN 1/1 Trays | |

| PWD 8628 | 1150x990x2500mm | 351L | Up to 18 DIN 1/1 Trays |

Thank you for requesting a quote. A member of our team will be in touch shortly.

Thank you for requesting a quote. A member of our team will be in touch shortly.