US 100/200 Series Ultrasonic Washers

The series features AISI 316L grade stainless steel wash tanks fitted with industrial style transducers combined with a powerful ultrasonic generator to provide high-performance cleaning in a low maintenance durable unit. Critical process parameters such as temperature, ultrasonic power, and time are monitored, granting compliance to the international standards. The ultrasonic cleaning of US 100/200 acts on immersed surfaces thousands of times a second to ensure perfect cleanliness.

Home / Infection Control Washer Disinfectors / US 100/200 Series Ultrasonic Washers

Steelco US 100 front view

Click to see full view

Steelco US 100 Side view

Click to see full view

Steelco US 100 open view

Click to see full view

Steelco US 200 Side view

Click to see full view

Steelco US 200 Side view

Click to see full view

Steelco US 200 Open view

Click to see full view

Hover to zoom

US 100/200 Series Ultrasonic Washers

Steelco US 100 front view

Steelco US 100 Side view

Steelco US 100 open view

Steelco US 200 Side view

Steelco US 200 Side view

Steelco US 200 Open view

Our solutions are trusted by industry leaders for critical processes in Infection Control & Life Science sectors:

Key Features

-

High Productivity

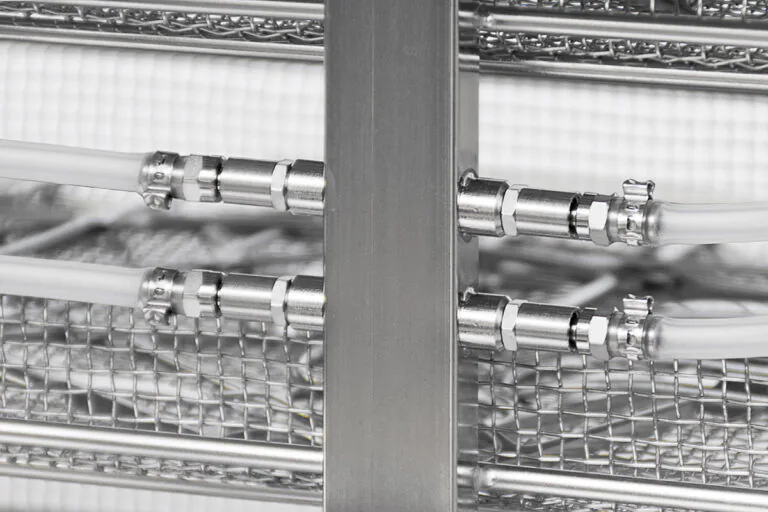

Up to 3 DIN 1/1 baskets with 12 luer lock connections, for each tank.

-

Design and Safety

High-quality stainless steel AISI 316L washing tank and stainless steel AISI 304 external body for long-term reliability and cleanliness.

-

Integrated Chemical Dispenser

Automatic chemical dosing pump and flow meter for chemical validation. Minimum chemical level control with alarm.

-

Flexible Solutions

Baskets can be loaded on three different levels, and the cycle is completely automatic. Each level has four luer lock connections for hollow instruments. The two upper levels are removable to allow the treatment of bigger instruments.

-

Cleaning Care Control Panel

No abrasives or harsh chemicals are used to guarantee maximum care for the most delicate and highly finished items.

-

Traceability

Port for printer connection to machine data updates. USB port for historical cycle data, machine parameters, and washing programs download.

Certifications

- Steelco Ultrasonic washers are designed and constructed to comply with the latest European guidelines on decontamination

- EN ISO 15883-1/2, CEN ISO/TS 15883- 5 and classified CE Medical Device (Community rule 93/42/CEE) code nr. 0051

Configurations

Model | Tank Configuration | Dimension WxDxH (mm) | Basket Capacity | Enquire |

|---|---|---|---|---|

| US 100 | 1 ultrasonic tank | 12 Luer lock connection | 800 x 700 x 950 | 3 DIN 1/1 net baskets per tank | |

| US 200/1 | 1 ultrasonic tank | 12 Luer lock connections+ integrated workspace | 1500 x 700 x 950 | 3 DIN 1/1 net baskets per tank | |

| US 200/2 | 2 ultrasonic tanks | 24 Luer lock connections | 1500 x 700 x 950 | 3 DIN 1/1 net baskets per tank | |

| US 200/3 | 1 ultrasonic tank | 24 Luer lock connections + 1 washing tank | 1500 x 700 x 950 | 3 DIN 1/1 net baskets per tank |

Thank you for requesting a quote. A member of our team will be in touch shortly.

Thank you for requesting a quote. A member of our team will be in touch shortly.