Cleaning, Disinfection, and Sterilisation are three key terms often used when discussing Infection Control processes.

There is an essential requirement that individuals correctly distinguish between the terms, to ensure that the Infection Control processes take place correctly.

As experts in Disinfection, Sterilisation and Decontamination, we ensure that your facility is issued with Infection Control consumables of the highest possible standard.

What is Cleaning?

Cleaning is defined as the removal of foreign material, such as soil or food residue, from objects and instruments.

The cleaning process is typically done through the mechanical use of water with detergents or enzymatic products. It is the same process as what you do with your laundry and dishes.

How to carry out the Cleaning process?

The cleaning process can be carried out through the use of mechanical units. One of the most used mechanical units in the Healthcare industry is an Ultrasonic cleaner, which utilises high-frequency sounds to remove dirt from instruments.

It has been proven that using mechanical equipment, such as Ultrasonic washers, to clean medical instruments has significantly reduced the number of microorganisms present on their surface.

Some cleaning solutions, such as a neutral pH detergent, offer proper soil removal and are compatible with most materials. This detergent can be used alone or as a supplement to enzymatic cleaners (chemicals that can attack fats, starches, or proteins), which improves the removal of organic material.

This, however, requires proper dilution, and it’s essential to check that the soiled material is compatible.

What is Disinfection?

Disinfection is a process that eliminates many, if not all, disease-causing microorganisms, with the only exception being bacterial spores on non-living objects.

How to carry out the Disinfection process?

In the Healthcare industry, high-level Disinfection is undertaken to ensure that process is carried out to the regulation’s requirements.

High-level Disinfection is defined as the complete elimination of microorganisms in or on an instrument, except for small numbers of bacterial spores.

In the UK this includes the removal of Mycobacteria (biofilm forming microorganisms such as pseudomonas). For example, Alcohol Ethyl alcohol has varying bactericidal and virucidal effects depending on its concentration against different microorganisms.

On the other hand, Isopropyl alcohol is only effective in direct contact. Unlike Cleaning detergents, its composition is not meant for all types of materials. Prolonged and repeated use in Disinfecting rubber tubing can cause it to swell and harden.

Chlorine is the most widely used chemical disinfectant in the form of sodium hypochlorite (also known as household bleach). With its wide range of antimicrobial activity, this inexpensive disinfectant is able to remove biofilms created by bacteria from surfaces.

Varying concentrations of chlorine can kill M. tuberculosis, C. difficile, and Candida species in minutes.

What is Sterilisation?

Sterilisation is a procedure that breaks up all forms of microbial life.

Healthcare facilities perform the process through the use of physical or chemical methods.

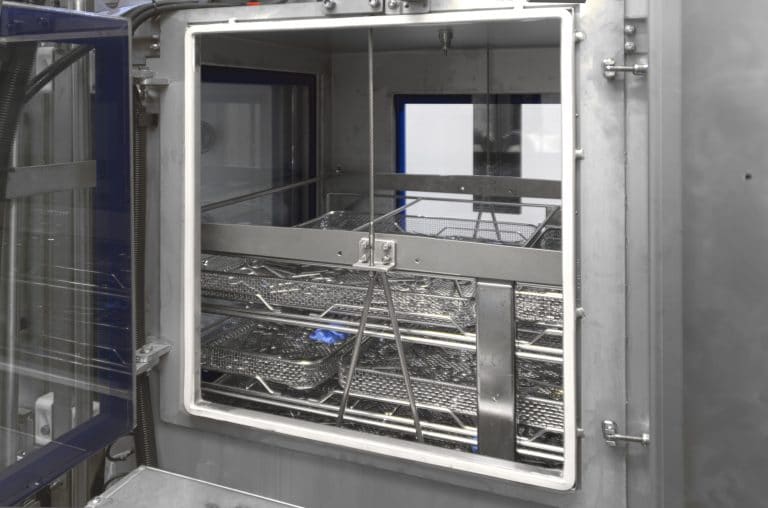

At Sychem, we, in partnership with the Italian manufacturing giant Steelco, offer various autoclaves to sterilise surgical instruments and other medical devices.

We provide an array of small, medium and large capacity steam sterilisers for use in CSSD and decontamination services units, ranging from compact 94-litre capacity autoclaves to large capacity steam disinfection units with capacities of 3806-litres.

In 2020 Sychem was awarded the NHS framework for Pathology and Point of Care Testing, Associated Equipment, Instruments, Consumables, Accessories, and Managed Services. Therefore, we are providing pathology laboratories with a range of decontamination equipment.

Our complete portfolio of autoclaves for the Healthcare industry is comprised of steam sterilisers and low-temperature sterilisers.

Want to find out more about each of these processes? Contact our team of experts today!

Can’t quite find what you’re looking for? Visit the Steelco website for more information.